Color in Refined Fuels

Measuring Color in Refined Fuels

Many liquid product specifications are based on color measurements. Changes in color can be an indicator of final product quality as well as a means to control process variables when implemented in real-time. Several different color “scales” are utilized in measuring color in different products or industries. Some common examples are ASTM color, Saybolt, and APHA (aka Platinum-Cobalt, or Hazen).

Online Monitoring of Saybolt Color with a ClearView db Photometer

In the past monitoring refined fuel color changes was accomplished by a grab sample technique or required an observer to compare the color of a product sample to a known standard, and then judge the “color”. This one-point-in-time sampling method along with human interpretation leaves room for error and inconsistencies. Now, these measurements are achieved with precise, repeatable and reliable analytical process monitoring instruments. By installing our inline monitoring instruments utilizing photometric and spectroscopic technology, refinery operators gain real-time knowledge to keep the refinery operating at peak performance throughout the process.

The Smart Choice for Reliable Measurement of Color of Refined Fuel

Our GUIDED WAVE™ color analyzers are built on the proven multi-wavelength GUIDED WAVE ClearView® db VIS-NIR Dual-Beam Photometer technology. This filter photometer is a dual-beam design that provides increased stability over other single beam photometers. These complete “ready-to-go” analytical systems include:

- The photometer or analyzer

- The fiber optic cables

- The sample interface

- The controller software and pre-calibration to the specific color application.

Another advantage of our GUIDED WAVE ClearView db analyzer platform is that it is configurable to many different color scale measurements in addition to those described here. The two-channel ClearView db analyzer can be configured for two different color measurements, such as ASTM and Saybolt, accomplishing both measurements with one analyzer, simultaneously.

TYPICAL REFINED FUEL COLOR MEASUREMENTS

- Crude Distillation Unit (CDU): Detect crude carryover in the refined products and cuts from the CDU unit

- Diesel Fuel Desulphurization Units: Verifying efficiency of the sulfur removal

- Natural Gas Liquids (NGL): Product quality and color verification at custody transfer points

- Lube Oil Processing Plants: Product quality and color verification

- Refined Fuels: Product quality and color verification after final processing and before the sale

SALES | TRAINING | SERVICE

Americas +1.916.638.4944

EMEA +49 69 20436910

China/APAC +86 400 086 0106

USEFUL NIR UV-VIS Troubleshooting Guides & Technical Resources

| APHA/Pt-Co | ASTM | Saybolt | Turbidity | Gardener | |

|---|---|---|---|---|---|

| Range | 0-500 | 0.5 to 7 | -16 to 30 | 1 to 6 haze, NTU 0-1000 | 1-18 |

| Lightest | 0 | 1 | 30 | 1 | 1 |

| Darkest | 500 | 8 | -16 | 6 | 18 |

| ASTM METHOD | D1209 | D1500, D1524 | D156, D6045 | D4176 | D1544, D6166 |

| Typical Configuration | APHA ANALYZER 30- or 50-mm SST Probe (Depends on high, low, or full-scale range) |

ASTM Analyzer 5mm Flow Cell |

Saybolt Analyzer 20- or 50-mm SST Probe |

Turbidity Analyzer Turbidity Probe |

5 mm Flow Cell |

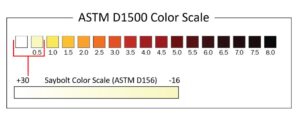

Saybolt color

Saybolt color (reference ASTM D156, ASTM D6045) is primarily used in characterizing fuels including automobile and aviation gasolines, jet fuel, diesel fuel, naphthas, kerosene, lubricating oils, heating oils, fuel oils, NGL and petroleum waxes. Saybolt is a lighter color range than ASTM. The Saybolt color scale goes from 30, which is considered to be barely perceivable yellow, to –16 which is a definite yellow. Products with a faint color below 0.5 ASTM are often defined by the Saybolt color scale. Both of these ASTM methods are off-line manual laboratory evaluations. The original test design required an observer to compare the color of a product to a known standard, and then judge the “color”.

The petroleum refining and petrochemical industries rely on Saybolt and ASTM color scales (among others) to quantify product quality.

APHA\Pt-Co (Hazen) Color

This test method describes a procedure for the visual measurement of the color of light-colored liquids. It can be referred to by several names: APHA (American Public Health Association), Platinum-Cobalt (reference ASTM D1209), or Hazen. The measurement was originally developed to detect contamination of water supplies as detected by a slight yellow color. Today it finds use in many industries to measure slight yellowness to determine product quality (either degradation or impurities).

The APHA/Platinum-Cobalt color scale is described in ASTM D1209 “Standard Test Method for Color of Clear Liquids (Platinum-Cobalt Scale)”. The ASTM method is an off-line manual laboratory method. This original test design required an observer to compare the color of a product to a known standard, and then judge the “color”. This color scale ranges from 0 to 500. The lowest value of 0 is referred to as water white. A value of 500 is distinctly yellow.

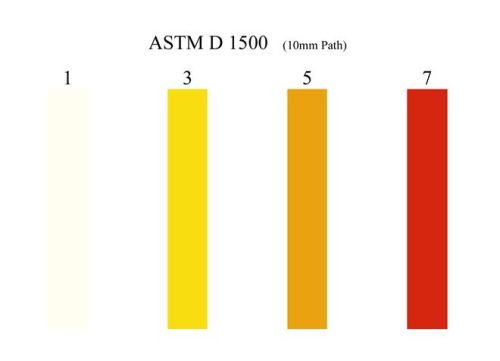

ASTM Color

ASTM color (reference ASTM D1500, ASTM D1524) describes the color measurement method for fuels including lubricating oils, heating oils, diesel fuels, and petroleum waxes. The color scale ranges from 0.5 to 8. The lowest value of 0.5 being a light yellow, 2 being yellow, 5 being orange, and 8 being a deep red. Both of these ASTM methods are off-line manual laboratory evaluations.

Turbidity (Haze) Color

Turbidity can be used to indicate solid breakthrough in a process. This can be used as an alarm and to invalidate other optical measurements until the problem can be corrected. Turbidity values can be found in several different units depending on the application. Two common measurement standards are ASTM Method D4176 (Haze), and EPA method 180.1 (NTU). The ASTM method describes the visual standard for measuring turbidity (caused by immiscible water in fuels) by viewing cards with black lines of various thicknesses through a 100mm diameter glass jar of solution. The result is a value (called Haze) between 1 and 6, with 1 being the clearest.

Haze is typically measured in the refining sector and arises from water contamination beyond the solubility limit. EPA 180.1 measures light scatter at 90 degrees in nephelometric turbidity units (NTU). In this method standards of formazin are available at different NTU levels to be used for calibration.

Gardner Color

Gardner color (reference ASTM D1544, ASTM D6166) is typically used in measuring drying oils, varnishes, fatty acids, polymers, and resins. The Gardner scale is from 1 through 18 with 1 being a light yellow and 18 being a deep reddish-brown. Standards for Gardner color can be made from metal salts used in the Platinum! Cobalt scale (for the lower numbers) and from ferric and cobalt chlorides dissolved in hydrochloric acid (for the higher numbers).

Our comprehensive GUIDED WAVE NIR UV-VIS process and lab analyzer spectrometers offer optically matched components and a meticulously planned calibration approach, ensuring long-term efficiency and cost savings. Our advanced systems are engineered for continuous online operation, delivering real-time data of laboratory-grade quality, even in the harshest processing plant conditions.