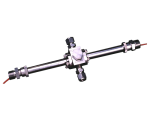

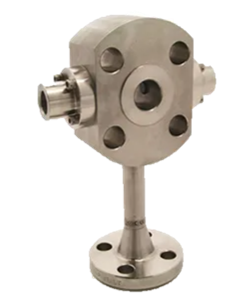

Our GUIDED WAVE™ High Safety Flow Cell (HSFC) was engineered for applications involving extremely hazardous materials. When processes involve extremely toxic or hazardous materials such as hydrofluoric acid, phosgene, isocyanates, etc., safety is paramount. Uncontrolled or undetected leaks cannot be tolerated. Our GUIDED WAVE High Safety Flow Cell (HSFC) was designed with leak prevention and early detection in mind. Built into a Class 300 flange, using welded construction, the HSFC uses double O-ring sealed sapphire windows. A weep or “tattletale” port connects to the space between the O-rings and when coupled to a sensor, can indicate O-rings in need of replacement. The GUIDED WAVE High Safety Flow Cell (HSFC) is available in a variety of alloys and O-ring materials selected to be compatible with your process.

High Safety Process Flow Cell Features

- Suitable for extremely hazardous sample streams

- Built into a ½” class 300 flange

- Patented Double O-ring sealed design

- Safety sniffer port provided between O-ring seals. This allows connection to a leak detection system to be used as an indicator of primary seal failure

- Compatible with all Guided Wave analyzers and many other analyzer brands

Safety Features of the Flow Cell

As a patented (US Pat #5,452,082) safety feature, each sapphire window is double O-ring sealed. A passage from between the O-rings is brought to a common port terminated in a ½” Class 300 flange. It is highly recommended that a sensor sensitive to the process material be attached to this port with its alarm set at an appropriate level. An alarm condition would indicate that the first O-ring seal has failed, and that immediate O-ring service is required. The second O-ring seals the process until the required service is accomplished.

Welded construction is used to connect the warning port. All HSFC’s are hydrostatically tested prior to delivery.

The GUIDED WAVE High Safety Flow Cell (HSFC) is a 2.25” thick, 1” Class 300 flange with double O-ring sealed sapphire windows. Precision mounted collimating lenses and fiber optic (SMA 905) connectors complete the optical design. Hardware is provided to connect protective conduit for the fiber optic cables. Standard optical pathlength are 20 mm and 30 mm. Other pathlengths are available by special request. Standard construction is 304 stainless steel; other alloys are available.

![NIR UV VIS APPLICATION QUESTIONNAIRE]](/wp-content/themes/yootheme/cache/d4/NIR-UV-VIS-APPLICATION-QUESTIONNAIRE-d40f8301.png)