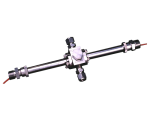

Our GUIDED WAVE™ RTD-SST (Resistance Temperature Detector) Process Probe gives reactor operators additional temperature data along with real-time near-infrared (NIR) measurements. By adding a Resistance Temperature Detector (RTD) to the industry-standard single-sided transmission (SST) probe, this fiber optic RTD-SST Probe provides more options for continuous process monitoring applications. The RTD-SST Probe is compatible with most analyzers and is easily installed in a pipe or reactor through a single access port. Older chemical plants or reactors without available access ports gain additional process analytical tool with this competitive solution.

RTD-SST Probe Configurations

The GUIDED WAVE RTD-SST (Resistance Temperature Detector) Process Probe is available in several configurations. One configuration includes the RTD built into the SST Probe at the path piece (tip). This design is for older reactors with no available ports and suits any flange size. The user can carry out a form-fit replacement of the existing thermal well and RTD. This RTD-SST probe provides better temperature compensation for NIR measurements than having an RTD and NIR probe installed on separate flanges.

- Corrosion resistant construction

- Rugged and vibration resistant design

- Sealed against ambient moisture infiltration

- High optical throughput for low noise spectroscopy

- Temperatures to 300 °C

- Pressures to 2000 psi or 138 bar

- Higher pressures are available on request

Exceptional Light Transmission

Like our other optical probes, the GUIDED WAVE RTD-SST Resistance Temperature Detector Process Probe provides exceptional optical performance. Typically, peak transmission exceeds 40%. That means more signal, lower measurement noise, and lower limits of detection.

Process-Resistant Probe Body Construction

The SST Probe is designed to withstand harsh process conditions. The body of the probe is built from 316L stainless steel or, by special order, other corrosion resistant materials. The SST Probe’s sapphire optical windows are sealed to the probe body with proprietary gold alloy brazing. These materials are unaffected by most hydrocarbons and polymers. Additionally, our special construction techniques also make the probe insensitive to most process pipe vibrations.

![NIR UV VIS APPLICATION QUESTIONNAIRE]](/wp-content/themes/yootheme/cache/d4/NIR-UV-VIS-APPLICATION-QUESTIONNAIRE-d40f8301.png)