Thermally Stable NIR

Fiber Optic Cable

THERMALLY STABLE NIR FIBER OPTIC CABLE

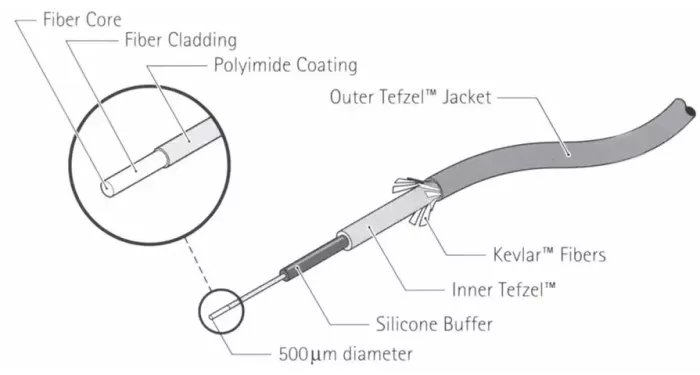

Signal stability and low noise in remote spectroscopy depend upon fiber optics with high transmission. Ideally, the transmission should be affected very little by environmental influences such as temperature, vibration, and ambient light levels. Based on a patented fiber design our GUIDED WAVE™ spectroscopic grade fiber optic cable is designed for the highest performance in transmission efficiency and durability. For near-infrared fiber, a polyimide coating and a patented silicone-based buffer protect the fiber from thermal stress.

The standard thermally stable NIR fiber optic cable receives a tough outer jacket made of Tefzel™ and inner Kevlar™ strands for strength. This rugged design prevents damage during installation.

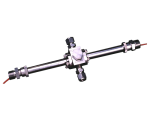

Inexpensive 200-micron telecommunication/consumer grade fiber optic cables are not appropriate for spectroscopic applications, as they cannot bring enough light to the detector. We provide 400-, 500-, and 600-micron fiber optic cables. The GUIDED WAVE NIR-O Process Analyzer Spectrometer and ClearView® db Dual Beam Photometer are optically matched to the 500 micron fiber, as it provides the best compromise between flexibility for installation and light throughput.

MANUFACTURING HIGH PERFORMANCE FIBER

All of our NIR fiber optic cable is constructed as a core-and cladding composite. The core, the filament that guides the light, consists of a thin strand of high transmissivity fused silica. The cladding is an outer layer of doped, lower refractive index fused silica. This two-layer design keeps the light tightly confined to the central core of the fiber thus delivering a maximum amount of light at the far end. The diameter is tightly controlled during the fiber drawing process. This produces a fiber that centers extremely well in connectors and has a very low loss rate per kilometer.

Unprotected silica fiber is quite fragile. To improve the fiber’s strength and flexibility, it is coated with a polyimide material during the drawing process. Then, another protective layer is added, a carbon-loaded buffer of silicone RTV (U.S. Patent #5,381,505). The buffer reduces stray light, both external ambient light that “leaks” through the jacket and internal stray light or “cladding” modes. Finally, we add an outer protective jacket. Our “process fiber” – fiber optic cable for harsh environment applications or applications requiring long cable runs – receives a multi-layer jacket made of Tefzel™ and Kevlar™.

NIR FIBER JACKETING OPTIONS

- Process fiber cable: Tefzel™ Kevlar™

- Laboratory fiber cable: PVC-coated, steel monocoil jacket

- Armored fiber cable: Steel BX Armor with PVC Jacket (150 meter maximum length)

AVAILABLE NIR FIBER DIAMETERS

- 200 μm (15 meter maximum length)

- 400 μm

- 500 μm

- 600 μm

FIBER TERMINATION OPTIONS

- SMA 905

- FC

- Custom (call)

- Bifurcated (call)

- Unterminated

Ideal for contiguous process monitoring in industrial applications

Ideal for contiguous process monitoring in industrial applications

USEFUL NIR UV-VIS Troubleshooting Guides & Technical Resources

APPLICATIONS

- Crude Oil Processing

- Water in Solvents

- Polyurethane Synthesis

- Caustic in Water

- Online Monitoring of Saybolt Color with a ClearView db Photometer

- Probes and Flow Cells for Extreme Environments

- Learn how our GUIDED WAVE RUGGED PROBES & FLOW CELLS MEET REFINERY REQUIREMENTS.

- Interested in learning more about our GUDIED WAVE PROBES & FLOW CELL SAFETY STANDARDS?

- Water Analysis in an Alcohol-Brine Solution with a ClearView db Photometer

- Water in Acetic Acid & p-Xylene with a ClearView db Filter Photometer

- Styrene, Acrylonitrile & Methyl-Ethyl-Ketone (Mek) for Online Control on a Styrene Tower

- Ensure Proper Ethylene Glycol Production Yields using NIR Technology

- Improve Yield During Diisocyanate & Urethane Synthesis

- Fast Reliable Measurements of Polyurethanes

- Probes & Flow Cells for Extreme Environments

- Probes and Flow Cells for High Temperature and Hazardous Polymer Measurements

- Inline Transmission Probe For FT-NIR Measurements

- Online Monitoring of APHA Color (ASTM D1209) with a ClearView db Photometer

TWO KINDS OF NIR FIBER CABLE

Presently, we offer two different kinds of optical fiber optimized for your spectral region of interest. Each type can be jacketed as outlined above and terminated in SMA or FC style connectors. Cables and bare fiber are available in a variety of core diameters from 200 μm to 600 μm (contact Process Insights for alternatives). The type of cable you’ll choose depends on your application:

Thermally Stable Process Fiber provides the lowest possible amount of internal light attenuation. It is appropriate for visible or near infrared (VIS-NIR) spectroscopy. It is especially effective for applications that require increased sensitivity in the spectral region near 1385 nm or where very long cables are necessary (up to 300 m). This cable is effective over the spectral range from 400 nm to 2100 nm.

Lab Grade NIR Fiber, intended for short laboratory-bench runs, is typically sold with the lab NIR-O analyzer. This more flexible NIR fiber can be supplied in PVC-coated steel monocoil jacket, steel armored BX jacket, or PVC-zip tubing.

![NIR UV VIS APPLICATION QUESTIONNAIRE]](/wp-content/themes/yootheme/cache/d4/NIR-UV-VIS-APPLICATION-QUESTIONNAIRE-d40f8301.png)