CLEARVIEW Hydrogen Peroxide Vapor Analyzer System

Hydrogen Peroxide Vapor Analyzer System

Turnkey solution measuring hydrogen peroxide and water concentrations in vapor phase

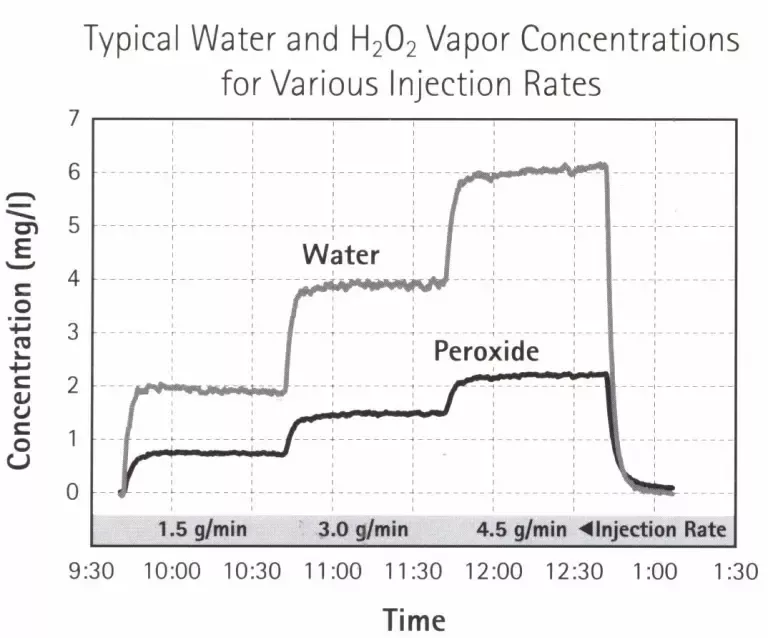

Our GUIDED WAVE™ ClearView® Hydrogen Peroxide Vapor Analyzer System is a simple turnkey solution for the measurement of hydrogen peroxide and water (H2O2 and H2O) concentrations in vapor phase. These are both measured together because they are codependent. The analyzer operates in real time, which takes the guesswork out of determining the H2O2 and H2O concentrations during cycle development and throughout the actual sterilization cycle. The user gains continuous, accurate data for documentation and validation.

Why is it important to measure hydrogen peroxide and water concentrations in vapor phase?

- Process control: H2O2 and water vapor concentrations are important parameters in several industrial processes, including sterilization, disinfection, and semiconductor manufacturing. Measuring these concentrations can help ensure process efficiency, consistency, and product quality.

- Regulatory compliance: Several industries, including healthcare and pharmaceuticals, have regulations and guidelines for H2O2 and water vapor concentrations in the air. Measuring these concentrations is necessary to ensure compliance with regulations and to protect public health.

- Environmental monitoring: H2O2 and water vapor can be emitted from industrial processes and can impact the environment. Measuring these concentrations can help identify potential environmental impacts and ensure compliance with environmental regulations.

- Occupational safety: H2O2 is a strong oxidizing agent that can be hazardous to human health if inhaled or ingested in high concentrations. Measuring the concentration of H2O2 in vapor phase can help ensure that occupational exposure limits are not exceeded, and workers are not exposed to unsafe levels.

OUR SYSTEM BENEFITS

- Real-time hydrogen peroxide sterilant gas monitoring

- Proven technology works in vacuum and atmospheric conditions

- H2O2 and H2O concentration by direct optical measurements

- Vital for resistometers and HPV cycle development

- Independent reference for HPV load production

- Optical RH and relative saturations measurement

LOW PRESSURE MONITORING WITH ACCURATE, RELIABLE RESULTS

Unlike chemical sensors, the GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System is able to measure H2O2 and H2O concentrations in vapor phase under ambient or vacuum conditions. Many processes use low pressure in the sterilization process to ensure penetration of product packaging. This system allows you to monitor these cycles so you can determine that the correct concentration of H2O2 and H2O were present during each cycle.

- Rapid response

- Multiple sample points on one analyzer

- Not subject to sensor poisons or analyte degradation

- Built-in validation available

PROVEN TECHNOLOGY

Our ClearView Hydrogen Peroxide Vapor Analyzer System utilizes a multi wavelength ClearView db filter photometer analyzer platform. Optimal wavelengths for H2O2 and H2O were selected to produce a simple yet rugged and reliable analyzer for this dedicated application. This new design uses fixed wavelength filter technology, yet still incorporates dual beam design for stability and accuracy. Fiber optic cables take the NIR light energy to the probe in the isolator and returns the non-absorbed light energy back to the analyzer – the optical equivalent of vapor sampling. The analyzer measures as low as 0.1 mg/L of H2O2 and 1.0 mg/L of H2O. With the addition of a temperature value, relative humidity and relative saturation measurements can be made.

APPLICATIONS

Here are some applications that use the GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System:

- Microbial contamination control

- Bioreactor and fermenter monitoring

- Quality control in pharmaceutical manufacturing

- Research and development in biotechnology and life sciences

- Medical device manufacturing

- Food and beverage processing

- Environmental monitoring and testing

Measuring H2O2 and H2O Under Ambient or Vacuum Conditions – Ideal

for Low Pressure Monitoring

Measuring H2O2 and H2O Under Ambient or Vacuum Conditions – Ideal

for Low Pressure Monitoring

APPLICATION SUPPORT

We offer many high performance, affordable, turnkey solutions for your application. Click here

FLOW CELLS & PROBES

Customized, innovative probes and flow cells designed to meet your specific process and safety needs.

USEFUL NIR UV-VIS Troubleshooting Guides & Technical Resources

INDUSTRIES

- Pharmaceutical manufacturing industry

- Sterile production areas, such as cleanrooms and isolators

- Used in other industries where hydrogen peroxide is used for sterilization, such as medical device manufacturing, biotechnology, and research laboratories.

The system is designed to measure the concentration of hydrogen peroxide vapor in real-time, providing critical information for the decontamination process. Hydrogen peroxide vapor is commonly used as a sterilization agent in these environments to ensure the elimination of microbial contamination. It’s a non-invasive and non-destructive tool that provides rapid, accurate, and reliable analysis of hydrogen peroxide vapor concentration. It helps to ensure that the decontamination process is effective and that the sterile environment is maintained.

Easy Operation and Control

The ClearView Hydrogen Peroxide Vapor Analyzer System is controlled via its touch screen or remotely via Ethernet (Modbus TCP/IP). All of the analytical calculations are encoded in the software. The complete system consists of a CLEARVIEW HVP Analyzer, one or two G-SST probes, and a pair of fiber optic cables for each probe. The analyzer is pre-calibrated at the factory. No programming is required by the user. Start-up requires powering the analyzer, connecting the probe or probes via the fiber optic cables, taking a ZERO reading in the dehumidified isolator and the H2O2 and H2O concentration measurements may begin.

ANALYZER OPTIONAL ENCLOSURES

Typically for medical, pharmaceutical and food industries, the ClearView Hydrogen Peroxide Vapor Analyzer System may be housed in a stainless-steel enclosure. Other enclosure options are available, such as, painted carbon steel, explosion-proof or purged depending on area classification requirements.

USER PROGRAMMABLE FEATURES

• Password protection for configuration changes

• Sampling time: 1 second minimum. User settable

• Reporting units: mg/L or ppm-V

ANALYZER SYSTEM ACCESSORIES AND OPTIONS

- 2nd channel for additional independent sampling point

- Custom length fiber cables

- KF or Tri-clover® flanged fiber feed throughs and dual fiber feed throughs

- Annual factory calibration service available

- Universal power supply (110-240 VAC converter to 24 VDC)

- Custom calibration for elevated temperature on request

FIBER CABLE

• 500 µm Ultra Low-OH fiber with stainless steel SMA-905 connectors

• Kevlar® protected or armored cables available

THE SMART CHOICE FOR RELIABLE MEASUREMENT

Our GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System delivers accurate, real time H2O2 and H2O measurement results. Its long-term stability and no maintenance requirements make it a cost effective, smart choice to help optimize production and ensure product quality ultimately enhancing profitability. As an ISO 9001 certified company, we maintain expert technical support and responsive global service for the lifetime of the system.

APPLICATIONS OVERVIEW FOR NIR UV-VIS PROCESS AND LAB ANALYZER SPECTROMETERS

| Key Word | Industry | Application Title | Description |

|---|---|---|---|

| APHA | Petroleum | On-Line Monitoring of APHA Color | APHA is sometimes referred to as the Platinum- Cobalt (Pt/Co) or Hazen scale. Also referred to as a “yellowness index”, the APHA color scale is a common method of comparison of the intensity of yellow-tinted samples to assess the quality of liquids that are clear to yellowish in color. Discover how real-time monitoring of APHA color either on-line or in a laboratory setting using a photometer can improve your process. |

| Aromatics | Petroleum | Monitoring the Percent Aromatics in Gasoline by NIR | The aromatic content of gasoline determines many of its combustion properties. Since it also impacts the environmental characteristics of the fuel it is desirable to have accurate measurements of this parameter. The traditional analytical method for measuring aromatics is either gas chromatography (GC) or an older method entitled fluorescent indicator adsorption (FIA), both of which are time and labor intensive. Learn how Guided Wave hardware and software can provide real-time measurement of % aromatics in fuel products using fiber optic-based, Near-Infrared (NIR) spectroscopy. |

| ASTM Color / D1500 / D1524 | Petroleum | On-line Monitoring of ASTM Color (0-7) With a ClearView® db Photometer | ASTM color (reference ASTM D1500, ASTM D1524) describes the color measurement method for fuels including lubricating oils, heating oils, diesel fuels, and petroleum waxes. The lowest value of 0.5 being a light yellow, 2 being yellow, 5 being orange, and 8 being a deep red. ASTM color is an important product quality measurement for many refinery and petrochemical processes. |

| Benzene | Petroleum | Benzene in Gasoline | The NIR spectra of a group of 150 different process gasoline samples with known benzene concentration ranging from 0.2 to 6.0% were measured between 1000 and 1600 nm using a GUIDED WAVE NIR Spectrometer. NIR is a time and money saving alternative to traditional methods. |

| Cetane Number | Petroleum | Cetane Number of Diesel Fuels | The Cetane number of a diesel fuel is a measure of the ignition properties and is an important specification that must be met during fuel production. The traditional laboratory method for Cetane number determination is the knock engine method in which the fuel is burned and its combustion characteristics compared to known standards. This method is time and labor intensive, and provides no ability for real-time control of production. This note discusses the use of GUIDED WAVE hardware and software for the measurement of Cetane number in diesel fuel using fiber optic-based, Near-Infrared (NIR) spectroscopy. |

| Styrene | Chemical | On-Line Control of a Styrene Tower | A ClearView db Photometer was installed at a Styrene production tower to monitor the concentration of styrene in ethylbenzene in the presence of toluene and benzene. The MLR calibration for styrene in 10 overhead samples resulted in an (R2>.9999) with a standard error of 0.84% styrene. |

| Ethylene Dichloride | Chemical | Safe Operation of your EDC Reactor | Ethylene dichloride (EDC) plants need to monitor the ethylene content in the vent gas. By using Near Infrared Spectroscopy, the control systems can maintain a constant concentration in the vent gas and also ensure that the concentration is maintained at safe levels during start-up. |

| Caustic & Carbonate | Chemical | On-Line Monitoring of Caustic & Carbonate | Learn about the simultaneous measurement of caustic (NaOH) and sodium carbonate in aqueous process streams, particularly at low (<2%) caustic concentrations, using a ClearView db NIR photometer and fiber optic probe. |

| Atrazine | Chemical | Monitoring Triazines and their Precursors | Learn about the measurement of various triazines using fiber optic-based, UV-Vis spectroscopy. Atrazine is a common contaminant in ground and surface water where it is slow to degrade. Agricultural runoff is the major source of surface water contamination. The US EPA Maximum Containment Level Goal (MCLG) for drinking water is 3ppb. |

| Trubidity / Haze | Petroleum | On-Line Monitoring of Turbidity or Haze | Alongside the measurement of Color, Turbidity is a property of interest for monitoring the quality of a fuel. Learn how Guided Wave has developed a Color and Turbidity monitor which is directly compliant with ASTM method D4176. |

| Fuel Blending | Petroleum | Continuous Fuel Identification for Pipelines | Reliable, affordable, real-time identification of petroleum products flowing in pipelines can enable terminals to identify the ideal time (t90) to switch to the correct storage vessel. This helps to minimize waste and the need for reprocessing petroleum products. |

| Octane | Petroleum | Realtime Octane Number Determination | The Octane number rating of a gasoline is an indication of how the gasoline will perform under various engine conditions. Two different ratings are included: Research Octane Number (RON) and Motor Octane Number (MON). Finished gasoline must meet certain Octane number specifications. Thus refineries control this parameter during production and must certify that a gasoline meets specification before it is released. Learn how Guided Wave can help ensure proper Octance levels avoiding the delay of an engine knock test. |

| LNG | Petroleum | Color in LNG (liquefied natural gas) | Measuring the Saybolt or ASTM color online is a key parameter in many light hydrocarbon mixes, such as Liquid Natural Gas for quality control. Monitoring the color allows the refiner to verify that the product is within specification and identify any “out of spec” product for reprocessing before being sold. |

| Saybolt | Petroleum | On-Line Monitoring of Saybolt Color | Saybolt color (reference ASTM D156, ASTMD6045) is primarily used in characterizing fuels including automobile and aviation gasolines, jet fuel, diesel fuel and other petroleum products. The Saybolt color scale goes from 30, which a barely perceivable yellow, to –16 which is a definite yellow. Learn how Guided Wave can provide cost-effective, explosion proof, field ready Saybolt Color monitors. |

| Iodine | Petroleum | Iodine Value of Oils | An important characteristic of a fatty oil product is its iodine value (IV). This is a measure of the unsaturated fatty acid content and indicates the ease of oxidation or the drying capacity of the product. Empirically, the IV is expressed in terms of the number of centigrams of iodine per gram of sample. Learn how NIR can be applied in real time to directly monitor your process. |

| Ethylene Glycols | Chemical | On-Line Monitoring of Water in Ethylene Glycols | Concentrations ranging from 0-100% water in Ethylene Glycol, each at 20, 25, 30, 35, 40 and 45°C were scanned on a NIR-O Full Spectrum Analyzer. A four-wavelength multiple linear regression was performed, which resulted in excellent linearity (R2>.9999) |

| Dimethylformamide / DMF | Chemical | On-Line Monitoring of Water in Dimethylformamide | The ability to monitor low levels of water in dimethylformamide (DMF) is a key consideration in the production of 1,3 butadiene. The quality of the final product (purity) can be compromised when water in excess of 400ppm is present in the DMF solvent stream. NIR spectroscopy provides the ideal method for in-situ water measurement. |

| Polyurethane | Chemical | Measurements in Polyurethanes In Situ | Many aspects of polyurethane production such as isocyanate concentration can be measured using Near-infrared (NIR) spectroscopy. In situ monitoring in the reactor systems allows for control of important properties during the reaction and to determine the endpoint of the reaction, thus adding to the value and cost savings. |

| Polymer Resin Reaction Endpoint | Chemical | Determining Polymer / Resin Reaction Endpoint In Situ | Determining reaction endpoint in polymer/resin reactors is critical to achieve desired product properties, such as molecular weight. Knowing exactly when the reaction is over saves residence time and batch conversion time, and lowers the overall manufacturing cost. Learn how GUIDED WAVE can help save you time and money with in-situ reaction monitoring and spectroscopy based reaction endpoint monitoring. |

| Ethanol | Petroleum | Real-time Determination of Ethanol in Gasoline | Ethanol is now a common biofuel additive for gasoline. The additional oxygen in ethanol provides for a cleaner burning fuel. The data presented demonstrates the measurement of the ethanol content of fuel using near-infrared (NIR) spectroscopy. |

| Fuel ID | Petroleum | Product Pipeline Interface Detection by NIR Spectroscopy | Petroleum product pipelines provide an efficient method of delivering product to distribution terminals. These multi-purpose pipelines deliver many different fuels often injected into the pipeline in a sequential fashion with no physical barriers between products. The receiving terminal must detect and separate the products in order to send them to the appropriate tanks and also identify off-specification product. |

| Polymer Melts | Chemical | Online Monitoring of Polymer Melts Using UV Fiber-Optic Spectroscopy | Polymer performance is directly related to the level of stabilizer. As a result, measurement and control of the additive concentration that is melt compounded into the polymer is crucial. Making these measurements in the melt offers many advantages over current offline quality control methods such as gas chromatography (GC) and high-performance liquid chromatography (HPLC). This application note will discuss an online UV/VIS method for monitoring the levels of hindered phenols and phosphites in polypropylene. |

| Acrolein | Chemical | Safe and Efficient Control of the Acrolein Process | Acrolein (or propenal) is the simplest unsaturated aldehyde. It is a colorless liquid and is mainly used as a biocide or as a building block to other chemical compounds. Measurement of both the water and acetaldehyde concentration in the final product is required. Acrolein is toxic and, without online analysis, hazardous manual sampling will be needed. Near-infrared spectroscopy can provide rapid, real-time, in-situ analysis of the Acrolein cross-linking process. |

| Cloud Point | Petroleum | Cloud Point of Diesel Fuel | The Cloud Point of a diesel fuel is the temperature below which wax forms giving the fuel a cloudy appearance. This parameter is an important property of the fuel since the presence of solidified waxes can clog filters and negatively impact engine performance. The traditional laboratory methods for the measurement of Cloud Point are optical in nature, but rely on cooling the fuel for the wax formation to occur. Guided Wave’s NIR instrumentation can measure composition changes in the fuel that will be directly related to the wax formation and hence the Cloud Point. |

| Hydroxyl and Acid Numbers | Chemical | Hydroxyl and Acid Numbers in Resin Melts | Learn how to monitor your hydroxyl and acid numbers online in resin melt and determine what the process yield will be. Alternatively, monitor your reaction to determine the end of reaction across multiple products. |

| Water | Chemical | A Word (or Two) About Online NIR Water Measurements in Liquid Samples | Water is perhaps the most common measurement made in the near-infrared (NIR). This is due to its strong effect on product properties and chemical reactivity of the starting materials. Learn some useful facts to consider when monitoring aqueous solutions with near-infrared spectroscopy. |

| Saccharin | Chemical | Monitoring breakthrough of Low Level Organics in Water | Saccharin is used as a sweetener and preservative in pharmaceuticals, nutraceuticals, and food and as an agent in semiconductor plating baths. Molecules similar to saccharin, i.e. benzo substituted heterocyclic rings, are used in semiconductor cleaning solutions. These applications often require control of organic concentrations in water in the 100 ppm range and below. Using Saccharin as a model trace contaminant learn how NIR can be used to identify when levels warrant replacement of the filter or reaction bath. |

| Phosphoric Acid | Semiconductor | Automated Determination of Phosphoric Acid Concentration | The use of phosphoric acid solutions is common in the semiconductor industry to both clean and etch metal surfaces. The concentration of the phosphoric acid is important to optimize these processes. Typically the laboratory method used for this determination involves one or more titrations. Learn how spectroscopy can be used for online in-situ monitoring of Phosphoric Acid Concentration. |

| Solvents | Chemical | Monitoring Water In Solvents | Water can be detected at much lower levels in non-OH containing solvents since there is less interaction between the base solvent and the water. However, in OH containing solvents such as Methanol, water can be detected down to several hundred parts per million. The measurement of the water levels in solvents with NIR spectroscopy is both fast and reliable utilizing the Guided Wave hardware and produces results that are available in real-time (seconds) thus making it a valuable tool for process measurement. |

| Benzotriazole | Semiconductor | Automated Monitoring of Benzotriazole Contamination For the Semiconductor Industry | Benzotriazoles have many uses. They can be used in the semiconductor industry in wafer cleaning, an anti-freeze ingredient for de-icing airplanes, in photographic developing baths, as a corrosion inhibitor for copper and bronze, a UV stabilizer in some plastics, and as a precursor for many pharmaceutical compounds. Though benzotriazoles are readily water-soluble they are not significantly biodegradable or readily removed by common water treatment methods. UV spectroscopy is a useful method for online monitoring of wastewater for benzotriazoles contamination. |

| Tetramethylammonium Hydroxide | Semiconductor | Automated Determination of Tetramethylammonium Hydroxide in Water | For semiconductor wafer processing, the level of tetramethylammonium hydroxide in water is very critical in the developer blend system. The solution of tetramethylammonium hydroxide must be kept at 2.38%. The concentrations of tetramethylammonium hydroxide can be easily measured at 2.38% by near-infrared (NIR) spectroscopy with a Guided Wave fiber optic coupled NIR-OTM Process Analyzer to better than ±0.1 % v/v. Analysis time is under 50 seconds. |

| Hydroxyl Number | Chemical | Hydroxyl Number in Polyols | The use of polymeric polyols is commonplace in the manufacturing of polyurethanes and other specialty polymers. The hydroxyl number (OH#) is a measure of the concentration of the hydroxyl groups on the polyol. This is an important parameter to monitor and control during polyol production. Learn how NIR can be used for real-time monitoring of Hydroxy Number of polyol cross-linking reactions. |

| Binary Solvent Feed Mixtures for Liquid Chromatography | Pharmaceutical | Binary Solvent Mixtures for High-Performance Liquid Chromatography | Discover the comprehensive analytics capabilities of NIR for ensuring proper mixture ratios of analyte samples being injected into HPLC columns. The correct mixture ratio ensures efficient and correct separation of the chemical targeted for separation in pharmaceutical applications. |

| HPLC Binary Solvent Feed Mixtures | Chemical | Fast Online Analysis of HPLC Binary Solvent Feed Mixtures | Binary solvent mixtures are used as carriers in production scale pharmaceutical HPLC separations. Analysis of the mixture ratios is required prior to injection into the HPLC column. The correct mixture ratio ensures efficient and correct separation of the chemical targeted for separation. Learn how this can be achieved with NIR. |

| Ethylene Oxide / EO | Sterilization and Virus Deactivation | On-Line Monitoring of Ethylene Oxide Sterilization | Near Infrared Spectroscopy provides real-time measurement of ethylene oxide (EO) gas during sterilization cycles. Ideal for use in sterilizer applications, this technology provides real-time results to ensure method compliance. |

| Epoxy Value | Chemical | On-Line Monitoring of Epoxy Value | Real-time monitoring of the Epoxy Value enables you to see into the reaction and monitor the epoxide group content and ensure that proper cross-linking is occurring. |

| Hydrocarbon Gas Streams | Chemical | Online Monitoring of Hydrocarbon Gas Streams | A common concern of hydrocarbon vapors, especially in ambient air mixtures, is the concentration relative to the Lower Explosion Limit (LEL). GUIDED WAVE'S NIR instrumentation can make both qualitative and quantitative measurements in gas streams using long path gas cells coupled to our analyzer systems to monitor short-chain alkanes such as Butane. |

| Acetonitrile | Pharmaceutical | Monitoring Reverse Phase LC of Acetonitrile/Water in Pharma Applications | A ClearView db Photometer was used to monitor the Acetonitrile (ACN):water mobile phase gradients for the chromatographic separation of active Pharmaceutical ingredients. |

| Alcohol Brine Solutions | Chemical | Real-time Water Analysis in an Alcohol-Brine Solution | This application note indicates that a ClearView db fiber optic filter photometer with an analyzing wavelength of 1820 nm and a reference wavelength near 1050 nm can analyze water in the presence of alcohols and salt. |

| Acetic Acid-p-xylene | Chemical | Monitoring Water in Acetic Acid & p-Xylene | Water can be analyzed near 1380 nm, independent of p-xylene or acetic acid content. Multiple linear regression (MLR) system- atically investigates which wavelength or wavelengths provide a statistically acceptable calibration. The MLR results confirmed that water can be determined solely at 1390 nm, and that acetic acid and p-xylene can be determined using two wavelengths at 1140 and 1380 nm. |

| Acetone | Chemical | Monitoring Water in Aromatic/Acetone Mixtures | Samples containing isopropyl benzene, acetone and phenol in approximately constant ratios were measured with a NIR Spectrophotometer. It was found that water in complex mixtures can be measured with an accuracy better than ±0.01% (wt.). Moreover, the spectrophotometer can utilize multiple fiber optic insertion probes flanged directly into a reactor or column, or flow cells on a slip stream for improved cost per sample point. |

| Trazines | Chemical | Monitoring Trazines and their Precursors In Agricultural Runoff | Agricultural runoff is the major source of surface water contamination. The US EPA Maximum Containment Level Goal (MCLG) for drinking water is 3ppb. The UV-Vis region of the electromagnetic spectrum displays electronic transitions and is particularly useful for viewing conjugated and aromatic molecules. By measuring the UV spectra of a series of samples of known atrazine or atrazine derivative concentration, a quantitative model can be developed which will allow the measurement of future samples based only on their UV spectrum. |

| Liquefied Natural Gas / LNG | Petroleum | Detecting Various Levels of Color of LNG with High Accuracy per ASTM Method D156, D6045 | A GUIDED WAVE Saybolt Color Analyzer System was fully implemented for real-time color measurement of various grades of LNG (liquefied natural gas) product with multiple specification requirements. Since the GUIDED WAVEcustomer required the measurement of various grades of LNG, they could not use just a “go” or “no-go” color analyzer. They needed to find an analyzer that was able to detect varying levels of color with a high degree of accuracy in accordance with ASTM D156 and ASTM D6045. |

| Fertilizer / Nitrous Acid (HNO2) | Chemical | Nitrous Acid (HNO2) Measurement in Fertilization Plant | GUIDED WAVE’S dual-beam ClearView® db Vis-NIR Process System Analyzer was fully incorporated for plant-wide HNO2 measurement and optimization. A global firm specializing in agricultural products and environmental protection agents needed a solution to improve employee safety during the manufacturing process. After researching several technologies to measure HNO2 in the lab, they determined that GUIDED WAVE'S ClearView db Analyzer System was the best solution. |

| Caustics in Water | Chemical | Caustic in Water with a ClearView db Filter Photometer | Measuring NaOH concentration in water on-line with the ClearView® db filter photometer and a fiber optic flow cell in a slip stream. |

| RON / Research Octane Number | Petroleum | RON / Research Octane Number | A GUIDED WAVE dual-beam NIR Process Analyzer System was fully incorporated to measure Research Octane Number (RON) of reformate from a plant’s catalytic reformer. Accurate real-time measurement saved the company money in additional, unexpected ways. |

| Jet Fuel | Petrochemical | Jet Fuel | Jet fuel quality parameters such as Cetane Index(#), API Gravity, Viscosity, Aromatics, and Distillation (D10, DS0, etc) are all good candidates for measurement by NIR spectroscopy. |

| TMAH in Water | Chemical | TMAH in Water | |

| Polymer Melts | Chemical | NIR UV in Polymer Melts | |

| Water in Solvents | Chemical | Water in Solvents | |

| Water in DMF | Chemical | Water in DMF | |

| Water in Liquid Samples | Chemical | NIR Water Measure in Liquid Samples | |

| Water in Alcohol Brine | Chemical | Water in Alcohol Brine | |

| Water Aromatics Acetone Mix | Chemical | Water Aromatics Acetone Mix | |

| LNG (Saybolt) ASTM D156, D6045 | Petrochemical | Detecting Various Levels of Color (Saybolt) for LNG Saybolt Success Story; ASTM D156, D6045 | |

| Sulfuric Acid Concentration | Chemical | Sulfuric Acid Concentration with ClearView db Photometer | |

| ASTM D1500 | Petrochemical | determine ASTM (D1500) color with our cost-effective GUIDED WAVE ™ ClearView® db Dual Beam Fiber Optic Photometer. | ASTM color (reference ASTM D1500, ASTM D1524) describes the color measurement method for fuels including lubricating oils, heating oils, diesel fuels, and petroleum waxes. |

| Trace Copper Contamination | Semiconductor | Detecting Trace Copper Contamination in Electroplating Solutions (Trace Cu Detection in Acidic Silver/Tin Solutions) | Copper contamination is a major concern for the semiconductor industry. With the advent of Tin and Tin/Silver solders for Lead-Free/RoHS compliant electrodeposition, the risk of trace copper contamination (<20 ppm) due to leaching of copper into the acidic bath solutions requires real time monitoring to ensure proper plating. |

| Clearning Solutions | Semiconductor | Monitor Cleaning Solutions in Semiconductor Wafer Manufacturing Process | One major challenge in operating wet chemical cleaning processes is maintaining optimal bath conditions required for uniform cleaning, reduced cycle times and minimal product rework. As an added benefit, accurate analysis of bath conditions makes the most efficient use of costly ultra-pure chemicals, and reduces chemical waste. Learn how a ClearView db photometer can be used to Monitor Cleaning Solutions in Semiconductor Wafer Manufacturing Processes. |

| Hydrogen Peroxide | Pharmaceutical | Online monitoring of Hydrogen Peroxide Sterilization | GUIDED WAVE'S HPV analyzer is a simple turnkey solution for the measurement of hydrogen peroxide and water (H202) concentrations in vapor phase. These are both measured together because they are codependent. The analyzer operates in real time, which takes the guesswork out of determining the H202 concentrations during cycle development and throughout the actual sterilization cycle. |

| Styrene Acrylonitrile SAN Copolymer | Chemical | Online Process Monitoring of Styrene / Acrylonitrile / MEK (SAN Copolymer) | Proof of concept study for monitoring the concentration of styrene, acrylonitrile, and mek concentrations during the copolymerization of SAN. |

| Whole Room Vaporized Hydrogen Peroxide Monitoring | Sterilization and Virus Deactivation | Adapting NIR Technology for Whole Room Sterilization | Vaporized Hydrogen Peroxide can be monitored in sterile fill isolator areas and rooms used for biological experiments (Biosafety Level 3 and 4 rated labs) require periodic decontamination and virus deactivation. This application note demonstrates a successful installation at The National Cancer Institute (NIH) Research and Production Center at Ft. Detrick, Maryland. |

| Color in Refined Fuels | Petrochemical | Measuring Color in Refined Fuels | |

| Polyester (PET) Synthesis | Chemical | Near-Infrared Analyzers for Polyester (PET) Synthesis | Infographic that show cases various locations in Polyester (PET) that can benefit from NIR monitoring. |

| Polymerization and Nucleation rate, Crystallization growth rate, Particle Size | Chemical | Relating Particle Size and Turbidity With a ClearView db | Particle size information can be directly estimated because the ClearView db is capable of measuring the forward scattering at visible and near infrared wavelengths, and sideways scatter from the wide bandpass turbidity filter. The measurement of forward scattering at higher wavelengths allows for larger (>200 micron diameter) particles to be measured. The dual measurement allows for a customizable turbidity measurement |

| NIR Analyzers for Polyurethane Synthesis | Chemical | NIR Analyzers for Polyurethane Synthesis | Infographic that show cases various locations in Polyurethane Synthesis that can benefit from NIR monitoring |

| Viscosity in Polyurethane Polymer | Chemical | Viscosity in Polyurethane Polymer | |

| Crude Oil Processing | Petrochemical | Crude Oil Processing | |

| Dual Probe Polyurethane Synthesis | Chemical | Combining Process Rheology & Spectroscopy Measurements to Improve Batch Polyurethane Polymer Production | The control logic shown can be adapted as needed to meet the specific product requirements. During the first step, process spectroscopy is used to monitor the monomer conversion and weight average molecular weight. |