Sample Interface Selection

How to Select the Best Sample Interface for your Process

For Your NIR-UV-VIS Process & Lab Analyzers

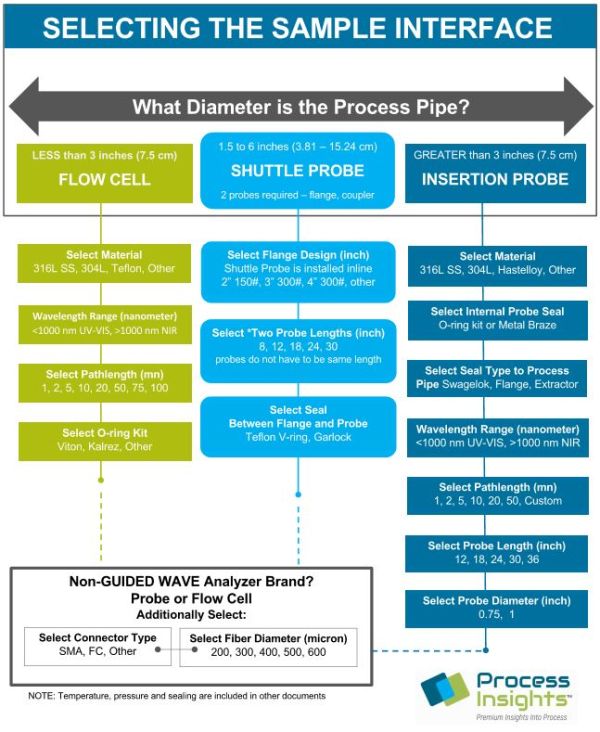

Perhaps the most critical decision in designing a successful online analyzer system is the selection of the sample interface.

HOW TO SELECT THE BEST SAMPLE INTERFACE

Perhaps the most critical decision in designing a successful online analyzer system is the selection of the sample interface.

We pioneered in-line fiber optic sample probes over two decades ago, with the introduction of the SST (Single Sided Transmission) Probe. This probe permits precise spectroscopic analysis of products directly in the process line without the need for sample systems and their associated investment and installation costs, lag times, failures, and constant maintenance requirements. When sample systems fail, reliable measurements stop, resulting in system downtime that is not the fault of the analyzer. Sample systems have their place and should be used when samples are particulate-laden, wet (2-phase), or overly temperature sensitive. Otherwise, in-line probes are the most cost-effective and trouble-free solution to real-time process spectral analysis.

While an insertion probe approach can often reduce installation costs, sometimes safety, servicing, and/or sample conditioning requirements make it necessary to integrate a sampling loop or slipstream. Flow cells are preferred whenever:

- Direct insertion probes are inappropriate and

- The required optical path length is 30 mm or greater

Another consideration is usability. All probes and flow cells must be referenced periodically. The period will depend upon the instrument and the process and may range from one hour to several months. Depending on the process, windows may become fouled in time and require cleaning. It is convenient if some accommodation has been made to either remove the probe from the process for these required services or to be able to perform them in place. We offer a probe extraction device and/or cleaning ports on the flow cell to facilitate this maintenance.

SELECTING FLOW CELLS

Insertion probes can be directly dipped into a laboratory beaker or inserted into a process pipe, so that the light is truly brought to the sample. However, in some applications, it may be more convenient to compromise and meet the sample halfway by using a flow cell. When it is not possible to insert a probe directly into a process line due to safety reasons, service requirements or the need to precondition the sample, a flow cell is the best choice. Optically establishing and maintaining alignment of the two halves and ensuring that the pathlength is constant and reproducible are key for continuous performance. Flow cells are convenient for their serviceability. They are usually mounted in a process side loop for maintenance reasons. Often, the seal technology is simple O-rings which require periodic service. Unlike most insertion probes, flow cells are designed to be disassembled in the field. On re-assembly, it is critical that the flow cell design is such that the pathlength returns to its original value. Some common convenient auxiliary features of flow cells may be thermal control, clean-out ports, and adjustable pathlengths.

SELECTING INSERTION PROBES

Selecting the proper probe is crucial to the success of the application. NIR and UV-VIS spectroscopy both cover many varied applications, which require a varied array of probes. While probes are predominantly passive devices in an otherwise active measurement system, their physical and optical properties can significantly add to or detract from the desired measurement. Effective pathlength, optical properties such as throughput, collimation, aberrations, sensitivity to vibration, sensitivity to thermal changes, and the quality of fiber connectors are important parameters in a probe design.

The probe is contained in a housing that must be sealed to the process to prevent the escape of the sample. The housing is usually metallic but may be glass, ceramic, polytetrafluoroethylene (PTFE), polymer or any material compatible with the process. The probe-to-process seal may be O-rings, energized seals, compression fittings, chevron seals, welded flanges, etc. The process conditions and parameters will mandate the seal and safety requirements.

SERVICING PROBES AND FLOW CELLS

No matter the manufacturer – all probes and flow cells used for absorption spectroscopy must be referenced (or zeroed) periodically. Furthermore, the windows may need periodic cleaning plus O-rings and other elements may need service. Practical methods for maintenance of the probe and flow cell, access to the windows, or complete disassembly and reassembly abilities must be considered when choosing new sample interfaces.

THE SMART CHOICE

Our sample interfaces deliver accurate, real-time process measurement results, durability, and low maintenance. Our sample interfaces are cost effective, the smart choice to help optimize production, improve yields, ensure consistent product quality and enhance profitability.

- For liquid or gas streams

- Optical measurement pathlengths from 1mm to 1 meter

- Customized, innovative designs to meet users’ specific process and safety needs

- Optically efficient designs which deliver more light, ultimately providing more chemical specificity and lower detection limits

- Rugged designs built to withstand harsh process conditions, while maintaining safety, ease of maintenance and longer service life

- Intrinsically safe designs – meets ANSI/ISA dual seal requirement and IEC 60079-28 standard

- CRN Certification available

- Common integration with most analyzers; manufactured to facilitate full integration with any fiber optic system configured with SMA905 connectors and fibers having a core diameter from 400 to 600 micron

The sample interface is a virtual “windows into the process” and is a critical component of any optical analyzer system. GUIDED WAVE sample interfaces (probes, flow cells) are designed for use with NIR or UV-VIS fiber optic coupled analyzers. They are designed to be rugged and reliable in harsh chemical and physical process conditions while providing optimal transmission for long-term reliable measurements.