QuickTOCtrace

TOTAL Organic Carbon water analyzers for Pure & ultra-pure water

Seamless Monitoring for Pure & ultra-pure water

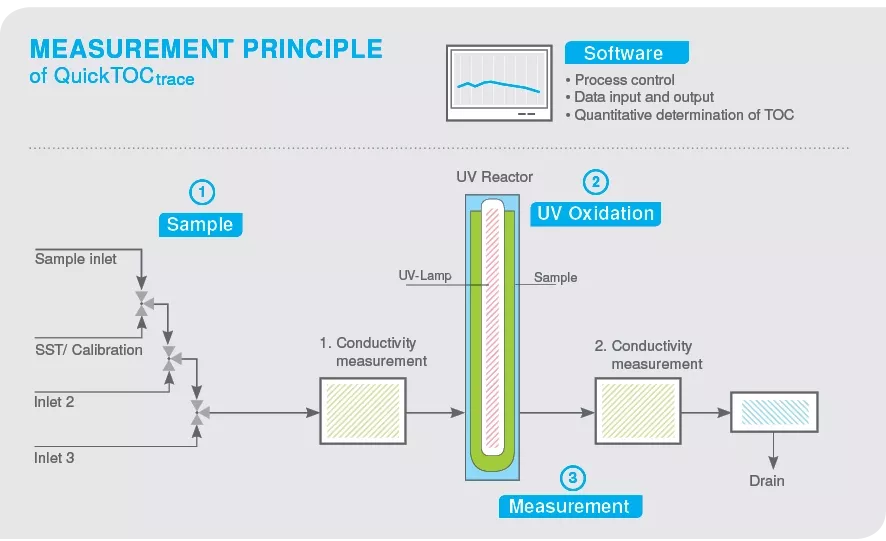

Our LAR™ QuickTOCtrace™ online TOC pure water analyzer is the most reliable measurement system for the determination of the total organic carbon. The QuickTOCtrace delivers the lowest measuring ranges, which uses UV oxidation and differential conductivity measurement to determine organic contamination, making it ideal for TOC measurement of ultra-pure water. It is a compact and intuitive analyzer with a short reaction time – first results are available within 30 seconds. It combines conductivity and UV oxidation to provide continuous TOC measurement in the 0.1 – 1,000 ppb range. Easy-to-use, this low-maintenance online analyzer quickly, and reliably monitors low-level TOC and is particularly well-suited for applications in the pharmaceutical industry (WFI, HPW, PW), and wherever ultra-pure water (UPW) is used.

The QuickTOCtrace online TOC pure water analyzer is a reliable analyzer for the lowest measuring ranges, which uses UV oxidation and differential conductivity measurement to determine organic contamination, making it ideal for TOC measurement of ultra-pure water. It is a compact and intuitive analyzer with a short reaction time – first results are available within 30 seconds. Using UV oxidation and differential conductivity measurement, the QuickTOCtrace reliably determines organic concentration results within 30 seconds.

This instrument is designed to monitor the quality of ultra-pure water with low concentrations of Total Organic Carbon (TOC). It is capable of measuring TOC concentrations as low as 0.5 parts per billion (ppb) in water samples. It is particularly useful for monitoring the quality of water used in critical applications where even low levels of TOC can have a significant impact on product quality and performance.

INDUSTRIES

The QuickTOCtrace online TOC pure water analyzer is used in industries that require ultra-pure water:

- Semiconductor manufacturing

- Pharmaceutical production

- Power generation

features & benefits

- Low cost of ownership, robust, and increases your processes seamlessly.

- Measuring range 0.1 to 1,000 ppb TOC

- Short reaction time → T90 within 30 seconds

- Continuous measurement (every 2 seconds)

- User-friendly software interface with 8“touch screen

- Remote service → connection to internet for service analysis

- Low operating costs → long lasting UV lamp

- Easy to maintain → easy to calibrate (1 time per year)

- Easy system validation with fully automatic SST (optional)

- Viewer → comprehensive data storage

OPTIONS

- Multi-stream measurement for up to 3 sample streams

- Calibration solutions

- SST-Kit

- Heat-exchanger for samples with > 50°C

HOUSINGS

- Housing Stainless Steel IP 20 (standard), IP 54 (optional)

Applications

- Pure water

- Ultra-pure water

- Process water

- Boiler feed water

- Condensate return

We are the TOC Leaders™

Monitor TOC, COD, BOD, TN, and Toxicity Impurities in all Types of Water

Monitor TOC, COD, BOD, TN, and Toxicity Impurities in all Types of Water

Do you have a LAR instrument?

Do you need technical support? Open a ticket.

Do you need technical support? Open a ticket.

GET A QUOTE TODAY | SALES | SERVICE | TRAINING

Americas +1 713.947.9591

EMEA +49 69 20436910

China/APAC +86 400 086 0106

CONTINUOUS TOC MEASUREMENT

The QuickTOCtrace pure water analyzer is an online system working on the basis of the traditional continuous flow process with conductivity detection. UV oxidation using the “direct surface” process guarantees highest precision thanks to highly sensitive conductivity sensors. In differential conductivity measurement, the initial conductivity before oxidation, as well as the conductivity after the treatment of the sample, are measured. The TOC concentration results from the difference obtained from subtracting the first, lower conductivity measurement from the second, higher one.

The verification of the TOC result is carried out using periodical implementation of the system suitability test and complies with the standards prescribed by the US pharmacopoeia, as well as the European pharma regulation (European pharmacopoeia). The QuickTOCtrace software enables a quick and simple initiation of the SST at any time and offers automatic data evaluation as well as automatic implementation of the testing procedure. The automized functions of the SST allow a high standard of safety and minimized operation costs in controlling the water.

WATER ANALYZERS BY INDUSTRY

REVOLUTIONIZE YOUR WATER ANALYSIS WITH OUR LAR™ TOC WATER ANALYZER: PRECISE, RELIABLE, AND EFFICIENT

Monitor TOC, COD, BOD, TNb, and Toxicity Impurities in all Types of Water

AEROSPACE & GOVERNMENT

LAB & RESEARCH

PHARMACEUTICAL & BIOTECHNOLOGY

by water type