Why Use Process Analytical Spectroscopy for Real-Time Monitoring?

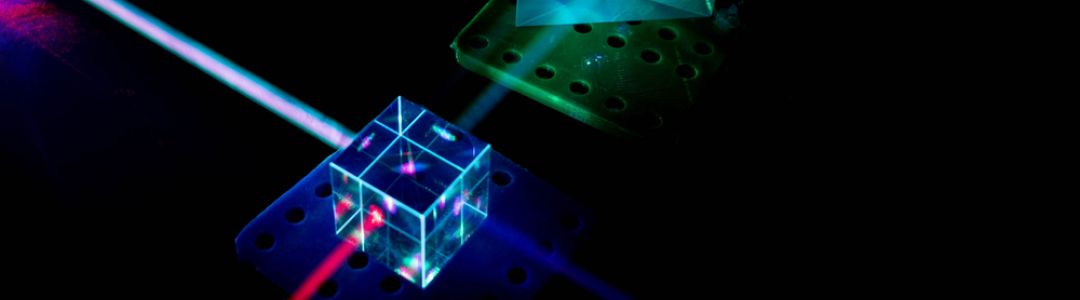

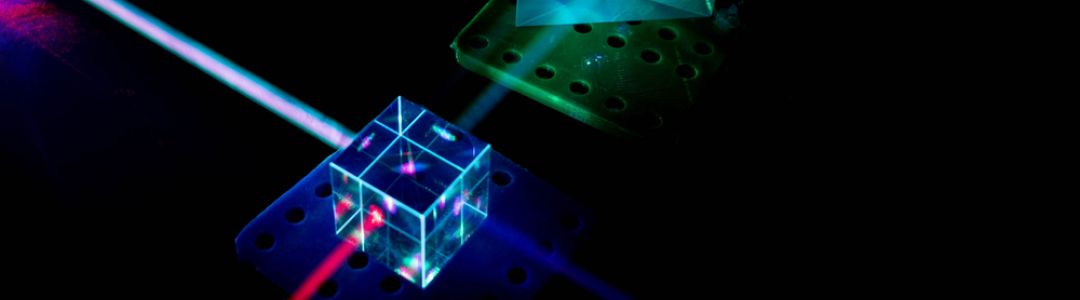

Traditionally, absorption spectroscopy has been used in laboratories to perform the precise analyses of samples. In recent years, as electronic circuitry and optical components have become more refined, a more robust portion of the electromagnetic spectrum – UV/VIS/NIR – has emerged for use in process analytical technology. No other technology matches the acquisition speed and the range of measurements returned by a fiber optic-based dispersive grating spectrometer. A comprehensive set of data that takes hours of laboratory analyses to acquire can be available in about a minute with a process spectrometer.

Process Analytical Technologies (PAT) have been field proven for almost three decades. It is typical for a Guided Wave scanning spectrometer running 24/7 to last more than 10 years with >99% uptime. The maintenance requirements for process spectrometers are also minimal in comparison to other monitoring techniques (for example, process gas chromatographs and online titrators). The return on investment and the low cost of operation makes Guided Wave analyzers a sensible and proven choice.

Near-infrared (NIR) spectroscopy is a non-destructive technique that can provide fast, accurate results of process conditions. NIR Spectroscopy is able to achieve real-time monitoring of multiple constituents in the process by illuminating the sample with light and analyzing how the light interacts with the sample. Spectroscopy achieves this without the high maintenance costs or the extensive upkeep considerations typically associated with gas chromatography (GC). Additionally, optical technology often eliminates the costly sample systems and fast loops needed for process gas chromatography.

NOTE: GC analyses can have significant annual costs associated with routine maintenance, column degradation, and carrier gas consumption. Such continual costs can be greatly reduced by replacing it with our Guided Wave inline spectrometer-based analyzer.