Jet Fuel Quality

Parameters

Quality Parameters for Jet Fuel Using a NIR-O Process Spectrometer

Modern jet aircraft require high quality fuel for optimal engine performance and safety. There are several different quality parameters of jet fuel that are typically measured. The reference methodology for these quality parameters often involve cumbersome and costly laboratory measurements. Near Infrared spectroscopy (NIR) provides an alternative approach to these measurements that is faster and more environmentally friendly.

Background

Jet fuel quality parameters such as Cetane Index(#), API Gravity, Viscosity, Aromatics, and Distillation (D10, DS0, etc) are all good candidates for measurement by NIR spectroscopy. Spectroscopic methods are faster and less labor intensive than typical laboratory methods, and they can also be used in both a process setting or in a laboratory. Use of spectroscopic methods in a process setting will allow the refiner to control the parameter during production.

This note will discuss the use of GUIDED WAVE™ hardware and software tools for the measurement of various jet fuel parameters using fiber optic-based, Near-Infrared (NIR) spectroscopy. The NIR-O™ process spectometer is designed for process use with built in multiplexing capability (multiple channels). NIR is a time and money saving alternative to traditional methods in both process and lab environments.

Reference Methods

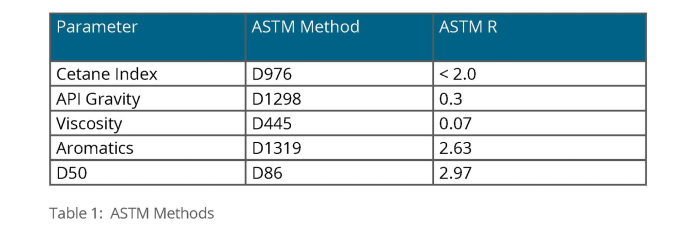

Each of the quality parameters of interest have a standard laboratory reference method, typically specified by ASTM. Table 1 lists the ASTM reference methods for the parameters described here. Each method has an associated reproducibility and repeatability statistic. Those statistics will be useful for comparison to the performance of the NIR spectroscopic method.

Measurement Background

The NIR region of the electromagnetic spectrum contains information from the overtone and combination bands of the C-H, O-H, and NH fundamentals. This information is related to the chemical composition and can be used for both quantitative and qualitative analysis. By measuring the NIR spectra of a series of jet fuel samples with known quality parameters, a quantitative model can be developed allowing the measurement of future samples based only on the sample’s NIR spectrum. Our analyzer systems use fiber optics to allow the sample probe to be located in remote locations away from the spectrometer itself. This facilitates the use of the analyzer in a process setting by having optical measurement probes located directly in the process flow.

SALES | TRAINING | SERVICE

Americas +1.916.638.4944

EMEA +49 69 20436910

China/APAC +86 400 086 0106

USEFUL NIR UV-VIS Troubleshooting Guides & Technical Resources

Experimental

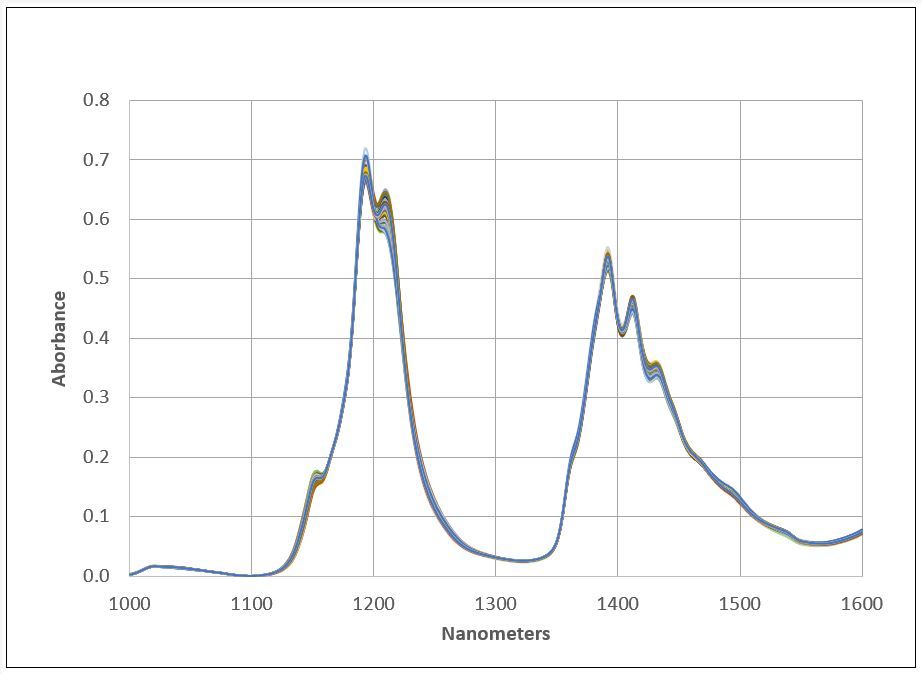

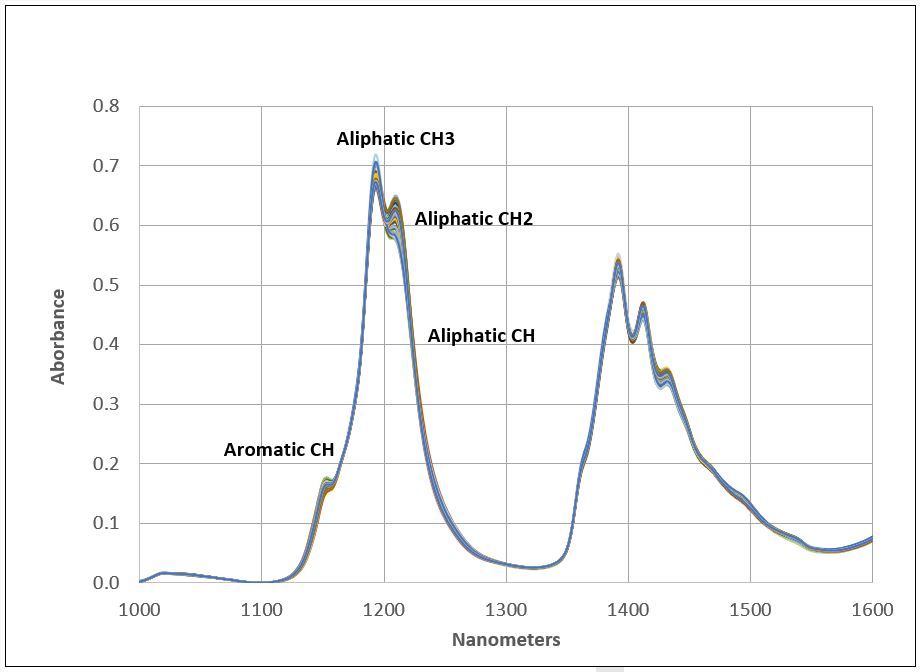

The NIR spectra of a group of different jet fuel samples (grades include Jet A, JPS, JP8, A-1) were measured between 1000 and 1600 nm using our NIR Spectrometer. Figure 1 shows the absorbance spectra of some representative samples collected using a sample probe with a 1 cm pathlength. The spectral region between 1100 – 1300 nm contains absorbance bands resulting from the second overtones of the various CH, CH2, and CH3 fundamentals. The region between 1300-1550 nm contains absorbance bands resulting from combinations bands of CH, CH2, and CH3. Since fuels are hydrocarbon based materials, we can use these spectral signatures in both quantitative and qualitative methods. Figure 2 shows some band assignments in the second overtone region.

Individual quantitative calibration models were created using the NIR spectra and laboratory reference data. The calibrations were generated using Partial Least Squares (PLS) regression. PLS is a widely used linear modeling method that allows the use of multivariate spectral data as independent variables in a regression model. In addition to being able to handle large multi-collinear data sets, PLS models enable the detection of outliers or unusual samples in future measurements. This can often be used as a mechanism for expanding the individual model’s range. For a discussion of PLS and other multivariate calibration techniques please see Martens & Naes1 and ASTM E16552.

Figure 1. Jet Fuel Spectral Data

Figure 2. Functional Groups

Results

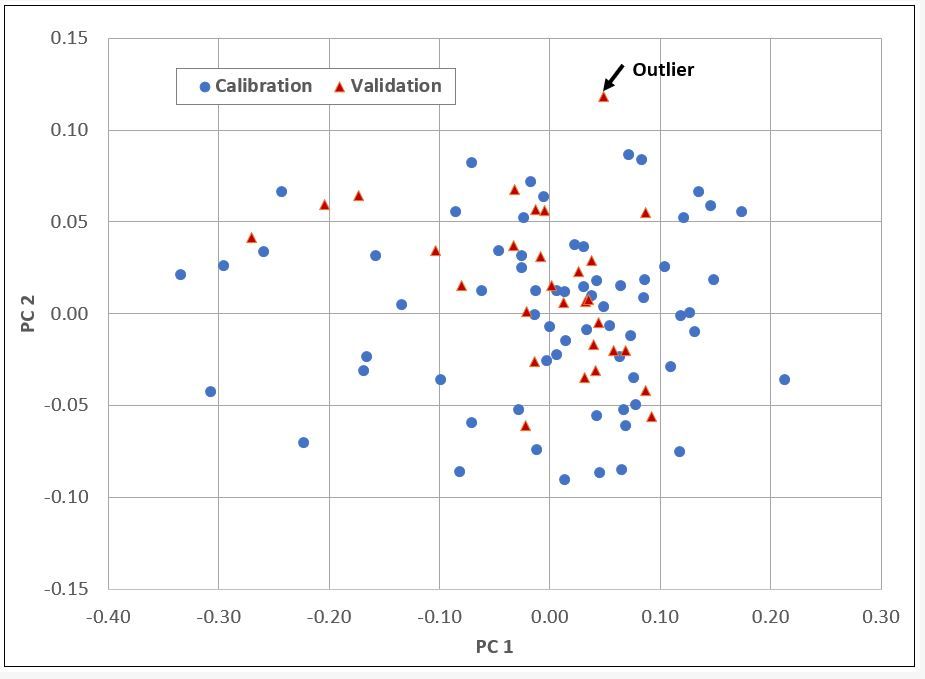

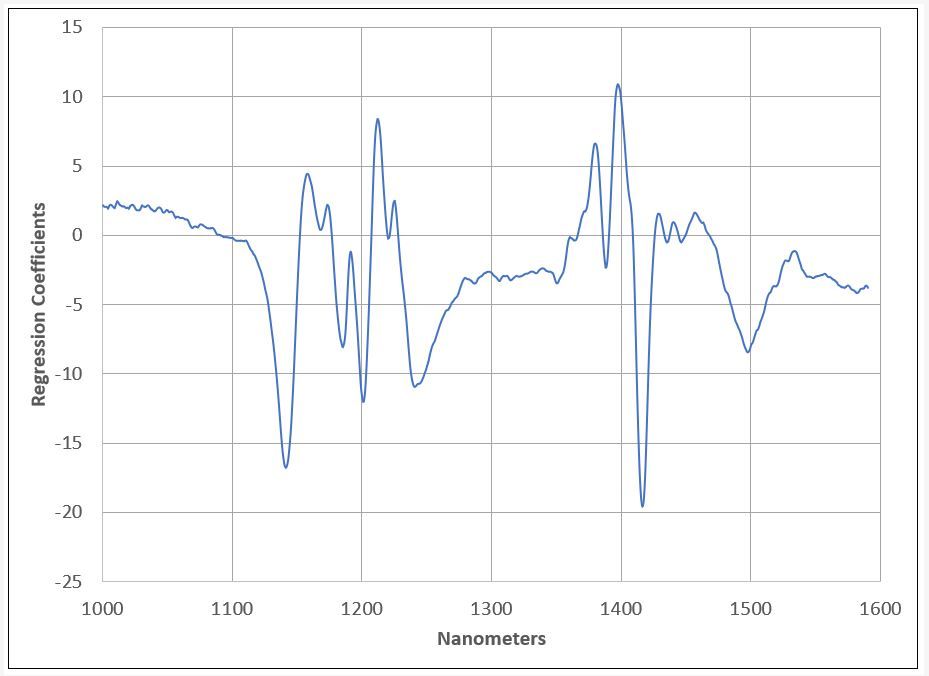

Multivariate calibration methods such as PLS allow the user to gain some insight into the overall prediction ability of the model. Typically, these methods present the user with a set of evaluation plots during development, showing the key parameters of the model. Figures 3, 4, and 5 show a few of these plots.

Figure 3 shows the individual sample scores from the Cetane calibration along with a set of validation samples (unknowns). This allows the user to evaluate how well the calibration (scores in red) describes unknown samples (scores in blue). In the Cetane example there is one sample highlighted that may not be described well by the model (a potential outlier). Figure 4 shows the final regression model equation. This allows the user to understand what regions of the spectral data are most significant. It also gives good guidance to help avoid overfitting the model and introducing additional uncertainty into the predictions.

Finally, in Figure 5 the predicted Cetane vs measured Cetane chart is shown for both the calibration model samples and the validation samples (unknowns) along with some prediction statistics. These charts allow the user to optimize the multivariate model for each individual parameter if needed.

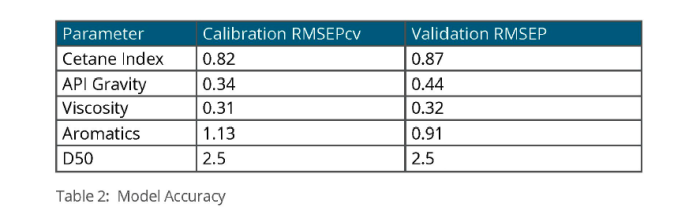

For the Jet fuel example, models were generated for each individual parameter and then used to predict a set of jet fuel validation samples (unknowns). These results are summarized in Table 2. All parameters are in good agreement with the accepted ASTM reference method.

Figure 3. Scores

Figure 5. Predicted vs. Measured

Figure 4. Regression Equation

Conclusion

The measurement of the jet fuel quality parameters using NIR spectroscopy is both fast and reliable utilizing our hardware and software tools as described here. This method minimizes the need for laboratory sample collection. Results are available in real-time (seconds) for multiple parameters in complex streams. For more detailed information regarding system specifications and the NIR-O process analyzer please contact a Process Insights sales or technical specialist.

References

- Martens, T. Naes, Multivariate Calibration, John Wiley & Sons, 1989.

- ASTM E1655 Standard Practices for ln-frared, Multivariate, Quantitative