Semiconductor

PROVIDING INNOVATIVE MEASUREMENT SOLUTIONS

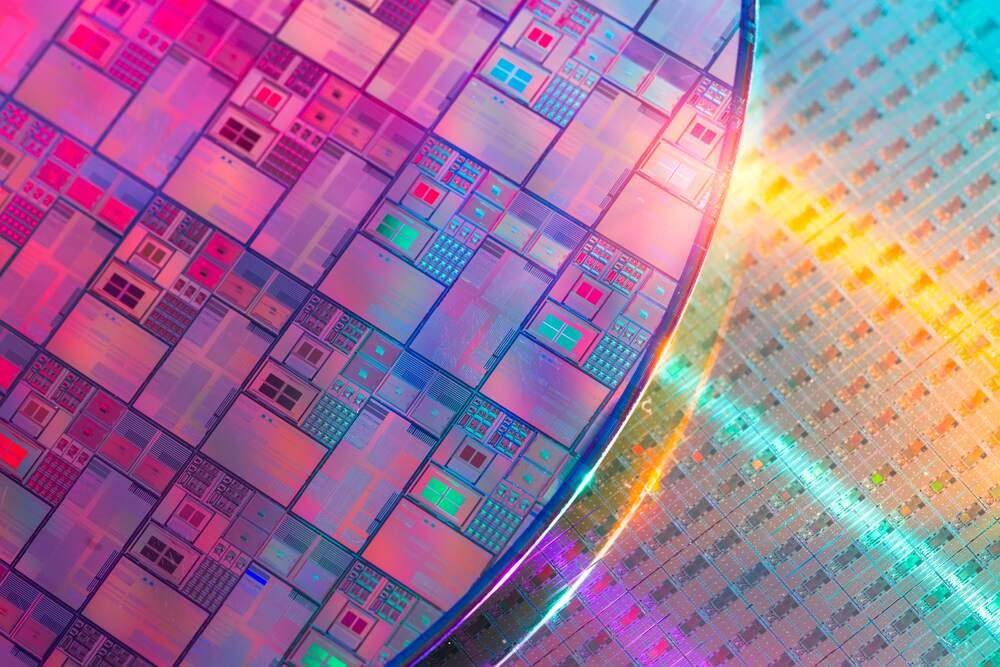

SEMICONDUCTOR INDUSTRY

Delivering Safety & Process Monitoring Solutions, You Can Trust

In the realm of the semiconductor industry, the significance of high purity gas analysis cannot be overstated. The gases employed during semiconductor fabrication undergo rigorous scrutiny because even minute traces of impurities can exert a substantial impact on the quality and reliability of the end product. This is particularly critical due to the exceptional sensitivity and high-speed, high-temperature operations of semiconductor devices, where even the slightest variations in composition or structure can profoundly influence their performance.

Throughout the various stages of semiconductor manufacturing, high purity gases play a pivotal role. The presence of even trace amounts of impurities within the gas can result in the incorporation of those impurities into the thin film, thereby compromising its quality. The implications of such compromised quality are significant, as they can lead to defects or failure in the final semiconductor device.

By conducting comprehensive and precise gas analysis, we enable the semiconductor industry to maintain the highest standards of purity throughout the manufacturing process. Our state-of-the-art analytical solutions are specifically designed to detect and quantify impurities, even at extremely low levels. Through real-time monitoring and analysis, we empower semiconductor manufacturers to identify any potential sources of contamination and take immediate corrective actions to ensure the integrity of the production environment.

We’re here to help. Contact us today.

EXPLORE Our CRDS Gas Analysis Portfolio

OUR CRDS ANALYZERS Deliver

- ppt-level analysis for CO, CO2 and CH4 impurities

- Continuous, real-time measurement

- High reliability, low maintenance

- Response time within seconds

- Low cost of ownership

- No calibration requirements

- No carrier gas requirements

- Easy to install, start up and use

TYPICAL CRDS APPLICATIONS

- Airborne Molecular Contaminants

- High-Purity Gases & Systems

- Low-Temperature SixGey Epitaxy

- Atomic Layer Deposition (ALD)

- MOCVD

- UHP Ammonia & High-Brightness LEDs

- Ultra-High-Purity Ammonia

featured products

NEW Tiger Optics™ T-I Max AIR

GREENHOUSE GAS MONITORING AT ITS BEST

Elevate your environmental monitoring with the new T-I Max AIRTM Cavity Ring-Down Spectroscopy (CRDS) Gas Analyzer from Process Insights. This cutting-edge analyzer delivers continuous, real-time monitoring of CO2, CH4, and H2O, making it an optimal solution for reporting mole fraction and monitoring atmospheric greenhouse gases. DOWNLOAD T-I Max AIR Flyer

NEW Tiger Optics™ Prismatic 3+

MULTI-GAS MONITORING AT ITS BEST

Introducing the TIGER OPTICS™ Prismatic 3+™ –With detection limits as low as 3ppb, our Prismatic 3+ Cavity Ring-Down Spectroscopy (CRDS) analyzers will reduce downtime and save money on preventative maintenance that is typically required by other technologies. The Prismatic 3+ laser-based, multi-species analyzer offers up to 4 analytes (H2O, CO, CO2 & CH4), providing measurements in seconds without the need for periodic calibration. Our CRDS analyzers are simple to install and operate, perfect for unmanned applications.

EXTREL™ VeraSpec™ APIMS

Semiconductor manufacturers need the ability to continuously verify the purity of process gases in real-time and detect trace contamination at concentrations in the low parts-per-trillion (ppt). Monitor a wide range of gases and gas mixtures with the stability that provides the long-term repeatability required in most applications.

-

AIRBORNE MOLECULAR CONTAMINANTS

In a cleanroom environment, where semiconductor manufacturing takes place, it is critical to maintain the air quality and prevent the introduction of any contaminants. Moisture and oxygen, in particular, can affect the quality and performance of the final product, and their levels must be monitored and controlled.

Our TIGER OPTICS™ CRDS (Cavity Ring-Down Spectroscopy) Gas Analyzers are also used in the semiconductor industry to measure and monitor the concentration of airborne contaminants, such as moisture and oxygen, which can adversely affect the semiconductor manufacturing process. They can measure a wide range of airborne contaminants, including moisture and oxygen. The CRDS analyzer provides real-time and highly accurate measurement of these gases, allowing for precise control of the manufacturing process.

DOWNLOAD Multi-Max AMC_Solution Brochure

-

BULK GASES

Our TIGER OPTICS™ CRDS (Cavity Ring-Down Spectroscopy) Gas Analyzers are used in the semiconductor industry to measure trace levels of impurities in bulk gases used in semiconductor manufacturing processes. These analyzers use a combination of laser-based spectroscopy and gas sample handling techniques to provide highly accurate and precise measurements of impurities in gases.

Our CRDS analyzers are used to measure trace levels of impurities in these bulk gases to ensure that they meet the required purity standards. The analyzers work by passing a laser beam through the gas sample in a high-precision optical cavity. The laser light is absorbed by the impurities in the gas sample, and the absorption is detected and quantified, providing a highly sensitive measurement of the impurity concentration.

-

ELECTRONIC GASES

In the semiconductor manufacturing process, electronic gases are used for various purposes, such as depositing thin films, etching, cleaning, and purging. The quality and purity of these gases are critical for achieving the desired performance of the final semiconductor product.

Our TIGER OPTICS™ CRDS (Cavity Ring-Down Spectroscopy) Gas Analyzers are commonly used in the semiconductor industry to measure and monitor the concentration of various electronic gases used in the manufacturing process. These electronic gases include silane, ammonia, nitrogen trifluoride, hydrogen, and other gases.

Our CRDS gas analyzers use laser spectroscopy to detect trace amounts of gases with high sensitivity and accuracy. They can measure a wide range of electronic gases, including impurities in these gases. The CRDS analyzer provides real-time and highly accurate measurement of these gases, allowing for precise control of the manufacturing process.

-

FAB SAFETY & COMPLIANCE

In the semiconductor manufacturing process, specialty gases are used for various purposes, such as doping, cleaning, and etching. The quality and purity of these gases are critical for achieving the desired performance of the final semiconductor product.

Our TIGER OPTICS™ CRDS (Cavity Ring-Down Spectroscopy) Gas Analyzers are used in the semiconductor industry to measure and monitor the concentration of various specialty gases used in the manufacturing process. These specialty gases include gases such as arsine, phosphine, and germane, which are used in the production of semiconductors for various applications.

Our other solutions include:

- Quadrupole Spectrometers used in semiconductor labs to measure the spectral properties of materials used in the manufacturing process.

- Water quality analyzers monitor the quality of water used in semiconductor manufacturing processes.

- Chilled mirror analyzers measure the dew point of gases, including dry air and process gases used in the semiconductor industry.

- Aluminum oxide dew point meters and transmitters use a sensing element made of aluminum oxide to measure the dew point temperature of the gas.

-

HIGH-BRIGHTNESS LEDS

It is essential to monitor impurities in high-brightness LEDs because impurities can have a significant impact on their performance and longevity. LEDs are highly sensitive electronic devices that emit light when current flows through them. Impurities, such as moisture or oxygen, can interfere with this process, leading to reduced light output, decreased efficiency, and shortened lifespan of the LED.

In the production of UHP ammonia, our TIGER OPTICS™ CRDS (Cavity Ring-Down Spectroscopy) Gas Analyzers are used to measure and monitor impurities such as moisture, oxygen, and nitrogen in the ammonia gas. Even small amounts of these impurities can affect the quality of the final product, so it is essential to ensure that the ammonia gas used in the production process is of high purity. The CRDS analyzer provides highly accurate and sensitive measurement of these impurities, allowing for real-time monitoring and control of the production process.

-

METAL-ORGANIC CHEMICAL VAPOR DEPOSITION

MOCVD is a key process used to deposit thin films of semiconducting materials onto a substrate, which is critical in the production of high-performance semiconductor devices. During the MOCVD process, a variety of gases are used, including metal-organic precursors, carrier gases, and reactant gases. It is important to monitor the concentrations of these gases in real-time to ensure precise control of the deposition process and the quality of the resulting films.

Our TIGER OPTICS ™ CRDS Cavity Ring-Down Spectroscopy (CRDS) gas analyzers can be used to monitor Metal-Organic Chemical Vapor Deposition (MOCVD) processes in semiconductor manufacturing. CRDS gas analyzers use a unique optical measurement technique to detect and quantify trace amounts of gases with extremely high sensitivity and accuracy.

-

PROCESS TOOLS

Semiconductor manufacturing requires a highly controlled environment with very low levels of impurities, as even small amounts of certain gases can cause defects in the final product. Therefore, real-time and accurate gas analysis is crucial in maintaining a stable and consistent manufacturing process.

Our TIGER OPTICS™ CRDS (Cavity Ring-Down Spectroscopy) Gas Analyzers are used as a process tool for the semiconductor industry for several reasons:

- Trace Gas Detection: CRDS technology is highly sensitive and can detect trace amounts of impurities in gas streams, making it an ideal tool for monitoring and controlling gas purity in semiconductor manufacturing processes.

- Real-time Monitoring: Provide real-time data on gas purity, allowing for quick identification of process issues and adjustment of gas delivery systems to maintain optimal conditions.

- High Accuracy: Provides accurate measurements of gas impurities, with detection limits down to parts-per-trillion levels.

- Easy to Use: Are easy to install, operate, and maintain, with built-in calibration and verification features that simplify routine maintenance.

- Versatile: Can be used to monitor a wide range of gases, including high-purity process gases, bulk gases, and gas mixtures.

- Process Control: Can improve process control, reduce yield losses, and ensure consistent product quality.

-

ULTRA-PURE & PURE WATER

Ultra-pure water is a critical component in many semiconductor manufacturing processes. It is used in a wide range of applications, including cleaning, rinsing, etching, and photolithography, and any impurities in the water can have a significant impact on the quality and performance of the final product.

Our LAR™ QuickTOCtrace™ TOC water quality analyzer is designed to monitor total organic carbon (TOC) levels in ultra-pure water. The analyzer uses a unique and highly sensitive technique known as ‘chemiluminescence’ to measure TOC levels in water samples. Some of the benefits of using the QuickTOCtrace analyzer include:

- High Sensitivity: Uses chemiluminescence technology, which is highly sensitive and can detect TOC levels as low as 0.5 parts per billion (ppb).

- Fast Analysis: Can analyze water samples in as little as three minutes, providing real-time data to operators and minimizing downtime.

- Wide Range of Applications: Can be used to monitor ultra-pure water quality in a variety of industries, including semiconductor manufacturing, pharmaceuticals, and power generation.

- Minimal Maintenance: Designed to be easy to use and requires minimal maintenance, reducing the need for downtime and saving on labor costs.

- Compliance with Regulations: Can help companies comply with regulatory requirements for water quality monitoring and avoid potential fines or penalties.

- Early Detection of Contaminants: Detects organic contaminants in ultra-pure water early, allowing operators to take corrective action before the quality of the end product is compromised.

-

WASTEWATER

Wastewater generated during the semiconductor manufacturing process contains a variety of contaminants, including heavy metals, acids, solvents, and other chemicals. These contaminants can pose a threat to the environment if they are not properly treated before being discharged into the environment.

Our LAR™ QuickTOCultra™ TOC water quality analyzer is used for the measurement of Total Organic Carbon (TOC) levels in semiconductor wastewater. Here are the some features and benefits:

- Measuring Organic Carbon Content: Uses the highly sensitive UV oxidation method to measure the total organic carbon (TOC) content of the wastewater.

- Wide Detection Range: Has a wide detection range making it suitable for monitoring the organic carbon content of a wide range of semiconductor wastewater samples.

- Rapid Response Time: Has a rapid response time of just 3-5 minutes, allowing for real-time monitoring of wastewater quality.

- Low Maintenance: Is a low-maintenance instrument, with no reagents or consumables required for operation.

- Automatic Cleaning: Features an automatic cleaning system that ensures reliable and accurate measurements over long periods of time.

- Remote Monitoring: Can be connected to a network for remote monitoring and control, allowing for convenient access to data and easy integration into a larger wastewater management system.