TOC Water Analysis

For TOC, COD, BOD, TN Water Quality Analysis

TOTAL ORGANIC CARBON TOC WATER ANALYSIS

Our LAR™ QuickTOCultra ™is the ultimate online TOC analyzer for determining total carbon (TC), total organic carbon (TOC), total inorganic carbon (TIC), and dissolved organic carbon (DOC), making it ideal for even the most challenging wastewater applications. With precise analysis at 1,200°C, our analyzer delivers accurate TRUE TOC measurements.

TOC Water Analysis is essential in many industries and applications, including:

- Drinking Water Treatment

- Wastewater Treatment

- Industrial Process Water

- Aquaculture Monitoring

- Environmental Monitoring

- Surface Water Management

- Pure & Ultra-Pure Water

- Deicing Management

Total Organic Carbon (TOC) analysis is a critical measurement in water quality management, offering fast, accurate insight into the presence of organic contaminants. At Process Insights, our TOC water analyzers are designed to meet the most demanding requirements across diverse industries and regulatory environments — helping you protect processes, ensure compliance, and maintain operational excellence.

Why Choose LAR TOC Analyzers?

- High accuracy and rapid response times

- Robust performance in complex matrices

- Low maintenance and minimal drift

- Flexible configuration options for lab, online, or field applications

- Compliance-ready reporting features for regulated environments

SALES | TRAINING INQUIRIES

AMERICAS: info.americas@process-insights.com

EMEAI (includes India): info.emeai@process-insights.com

APAC: info.apac@process-insights.com

CHINA: info.cn@process-insights.com

Total Organic Carbon (TOC)

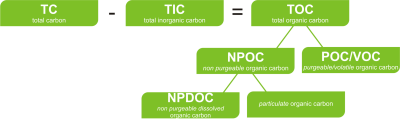

The Total Organic Carbon (TOC) is one of the most important composite parameters in the assessment of the organic pollution of water. Since it includes all carbon compounds as one mass, it is exactly defined and an absolute quantity. Therefore, it may be determined directly. In relation to the TOC also parameters like TC, TIC, DOC, (POC, VOC) are mentioned. The connections between these sum parameters and their meanings are shown in the following figure:

Definition of TC, TIC and TOC

Extracts of DIN EN 1484:1997-08

- TC- The organic and inorganic carbon in water, including the elemental carbon“.

- TIC – The carbon contained in water; elemental carbon, total carbon dioxide.

- TOC – The organic carbon in water, bound on dissolved or suspended substances. Elemental carbon will be also determined.

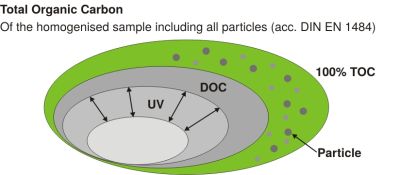

The total organic carbon (TOC) is a measurement method for the content of carbon of dissolved and undissolved organic substances in water.

Online TOC Measurement Methods

In general, the TOC is determined by oxidizing a water sample. The produced CO2 is detected and defined quantitatively. However, not all methods succeed in the complete oxidation of a sample. Often enough this may result only in SOC (Some Organic Carbon) instead of the TOC.

Thermal Oxidation

With this oxidation method the sample will be combusted in a reactor. Usually, a maximum temperature of about 1,000°C will be reached, which however does not allow the complete oxidation of all carbon compounds. Therefore, a catalyst, such as copper oxide or platinum, must be used at these temperatures. Normally, the catalytic combustion method can handle a TOC concentration of up to 4,000 mg/l. To reach higher ranges the sample usually needs to be diluted with Demin water.

LAR offers a unique and patented high temperature (HT) method at 1,200°C. This temperature enables the complete oxidation of all carbon compounds without any catalysts. It measures TOC concentrations up to 50,000 mg/l without dilution. In a special heat-resistant ceramic reactor, the water sample is evaporated, and all carbons are completely oxidized to CO2 gas. Afterwards, the CO2 concentration will be analyzed with a Non-Dispersive Infrared (NDIR) detector. Thus, the TC, TOC and TIC can be determined within only 3 minutes.

This ultra-high temperature method is used for both, the most challenging and highly contaminated waters (QuickTOCultra, QuickTOCairport) and waters relatively free of solid maters (QuickTOCeffluent). LAR uses the batch injection method with the advantage that the analyzers can easily handle sticky, oily and hard to oxidize dissolved and suspended organics resulting in a fast, reliable and accurate analysis. Even with rapidly fluctuating TOC levels the correct TOC concentration will be measured, whereby peaks throughout the course of the day are determined without any memory or adsorption effects.

For applications with purified water, this LAR method allows the patented simplified, ready-at-any-time calibration and validation method (QuickTOCpurity, QuickTOCpharma).

Photochemical Oxidation (UV-Persulphate Method)

Here the TOC is oxidized by means of UV light and a digesting reagent, sodium persulphate, and the produced CO2 is measured with a NDIR detector. This method suits the determination of TOC in clean water (drinking water, condensate, boiler feed water), since particles are hard to oxidize completely. The QuickTOCuv combines this technique with the direct TOC method or Non-Purgable Organic Carbon (NPOC) method, whereby the continuously provided water samples will be treated in a multistage process.

Wet Chemical Oxidation

With this method the water sample is oxidized by means of strong chemicals as oxidants such as ozone, which are slightly dangerous to health and environment. The ozone oxidation acids and bases are used to adjust the pH value of the sample along the pH scale. However, the oxidation potential of such methods is relative, since particles and more complex carbon compounds can only be partially digested or not at all. With regards to the latest standards of occupational safety and environmental protection these methods are not recommended.