MAX300-RTG 2.0

Industrial Process Quadrupole Mass Spectrometer

Unmatched Quadrupole Mass Spec Technology

Powerful Mass Spec Technology with Convenient Touchscreen

Our NEW EXTREL™ MAX300-RTG™ 2.0 Real-Time Industrial Gas Analyzer with touch screen is an industrial gas analyzer for process control, environmental compliance, and ambient air monitoring. It uses cutting edge quadrupole mass spectrometer technology to deliver continuous online composition monitoring of industrial gas streams. Rapid, accurate gas analysis enables high-precision process control and increased production efficiency.

- Maximum ease of use with simple and intuitive touch screen interface

- Real-time gas analysis using powerful industrial mass spectrometry technology

- Complete quantitative stream composition: total application coverage with fewer analyzers required

- High sensitivity and wide dynamic measurement range (ppb to %)

- Flexible and versatile with multi-port stream selector for up to 160+ samples

- Industry-best customer support and applications team

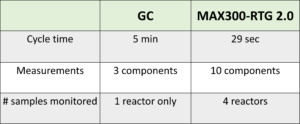

Our MAX300-RTG 2.0 Real-Time Industrial Gas Analyzer with touch screen has the speed necessary to analyze the total composition of a sample in seconds and can be fully automated to measure several points in a single process or multiple production lines across a plant with a single analyzer. With our Extrel industry-leading 19mm quadrupole mass filter, combined with state-of-the-art electronics, this mass spec delivers real optimized performance and more:

- Near-zero mass scale drift for outstanding measurement precision and stability

- Uniform resolution across the entire mass range for ultra-high sensitivity to all compounds

- Extreme resistance to corrosion and contamination

- Performance specifications superior to other mass spectrometers and commercial process technologies

The MAX300-RTG 2.0 is easy to use and has low maintenance requirements for industrial applications. You can easily measure multiple process points or production lines with one analyzer. It has the speed necessary to analyze the total composition of a sample in seconds and can be fully automated to measure several points in a process, or multiple production lines, with a single analyzer.

Easily measure all of the hydrocarbons in the feed gas stream as well as ppm contaminants, like H2S. Control parameters, such as BTU value, Specific Gravity, and Wobbe Index, are instantly calculated and transmitted for use by the plant’s process control system.

U.S. ENVIRONMENTAL PROTECTION AGENCY (EPA) REGULATIONS

On December 2, 2023, the U.S. Environmental Protection Agency (EPA) revealed its conclusive regulation aimed at significantly slashing methane and air pollution emissions originating from oil and natural gas operations. This comprehensive final measure, spanning over 1,600 pages, encompasses enhanced and updated standards for methane and other air pollutants from new, modified, and reconstructed sources. Additionally, it provides emissions guidelines to aid states in formulating plans aimed at curbing methane emissions from existing sources. Download the EPA Fact Sheet

For complete flare gas monitoring for compliance with regulations, our solutions include:

- Total Sulfur Excimer UV Gas Analyzers FGA-1000™ Flare Gas Analyzer

- Injection Style Calorimeter for Zero-Hydrocarbon Emissions for BTU and Flare Control 9800 CXi ™ Calorimeter

- Real-Time Mass Spectrometers for Compliance and Flare Control MAX300-RTG™ 2.0

Stay ahead of the curve – Process Insights can help ensure your flare gas meets the latest environmental guidelines. We offer single-source, complete solutions for your process analysis needs that align with the regulations – all tailored to fit your budget.

Gain Superior Process Control

BENEFITS

The MAX300-RTG 2.0 Real-Time Industrial Gas Analyzer uses an ionizer to break sample molecules into charged fragment ions that are then separated based on their mass-to-charge ratio as they move through the electric fields generated by the quadrupole mass filter. The ions register a current at the detector, creating a set of peaks called a mass spectrum. Each compound has a unique spectrum, making mass spectrometry a highly selective, flexible technique.

- Fast online gas analysis for increased manufacturing efficiency, product yield, and equipment uptime

- Full stream composition provides additional information necessary for advanced process control

- Lower capital cost compared to other technologies

- Automated online analysis and data delivery

- Control parameters reported in real-time

- Complete quantitative stream composition

- High precision and accuracy for optimal process control

- Low maintenance, utilities, and calibration required

- Reliable and accurate measurement for process automation and control

- Designed for product quality analysis

- Continuous, real-time analysis

- Full, speciated composition

- Unparalleled global customer service and support

Need help? Complete our Mass Spectrometer

Application Questionnaire.

Application Questionnaire.

APPLICATIONS

Flare Gas Analysis

- Ethylene Cracker Control

- Polyethylene

- Fuel Gas BTU

- Ethylene Oxide

- LNG

- PVC and EDC

- Benzene

Syngas Manufacturing

- Ammonia

- Methanol

- Hydrogen

- Gasification

- Acetic Acid

- Low-Sulfur Diesel

Metals Manufacturing

- Steel Carbon Content

- Blast Furnace Off Gas

- Coke Making

- EAF Monitoring

Gas Purity

- Trace Contamination

- Pharmaceutical Solvents

- Semiconductor Manufacturing

- Scrubber Efficiency

- Food and Beverage Gas

INDUSTRIES

- Environmental monitoring: Used to analyze air and water samples for environmental monitoring, such as detecting volatile organic compounds (VOCs) and other pollutants.

- Energy and power generation: Used to monitor gas emissions from power plants and other energy generation facilities, ensuring compliance with environmental regulations and optimizing energy production.

- Oil and gas: Used to analyze gases in the oil and gas industry, such as monitoring the composition of natural gas and detecting leaks in pipelines.

- Semiconductor manufacturing: Used to monitor the purity of gases used in semiconductor manufacturing, ensuring the quality and reliability of the final product.

- Pharmaceutical and biotechnology: Used to analyze gases in the pharmaceutical and biotechnology industries, such as monitoring the concentration of gases used in fermentation processes and analyzing off-gassing from drug products.

- Food and beverage: Used to analyze gases in the food and beverage industry, such as monitoring the concentration of gases in food packaging and detecting contaminants in beverages.

- Chemical: Can be used to analyze the composition of chemical products, ensuring that they meet industry standards and regulatory requirements. It can also be used to detect impurities or contaminants in chemical products.

- Petrochemical: Used to analyze the composition of hydrocarbon streams, such as natural gas, crude oil, and refined products. This can help petrochemical companies ensure the quality of their products and optimize their refining processes. It can also be used to monitor the emissions of gases from petrochemical manufacturing facilities, ensuring compliance with environmental regulations and reducing the impact of the facility on the environment.

Solutions Flyers

-

AGRICULTURE

-

CHEMICAL

-

ENERGY

-

FOOD & BEVERAGE

-

FLARE GAS

-

INDUSTRIAL GAS

-

LAB & RESEARCH

-

PHARMACEUTICALS & LIFE SCIENCE

-

REFINERY

-

SEMICONDUCTOR

-

SPECIALTY GAS