MAX300-TGM

Toxic Gas Analyzer for Air and

Environmental Monitoring Applications

Environmental Monitoring Applications

MASS SPEC TECHNOLOGY FOR Toxic gas monitoring applications

Real-time, monitoring using powerful quadrupole mass spectrometry technology

Our EXTREL™ MAX300-TGM™ Toxic Gas Monitor is designed specifically for monitoring:

-

-

- Operating Breathing Zone

- Process Tools

- Gas and Chemical Storage

- Gas Cabinets

- Valve Manifold Boxes (VMBs)

- Exhausted Enclosures

-

This real time monitoring solution has analysis speeds of 0.4 seconds per chemical and gas clearing times of less than 3 seconds. These impressive speeds exceed industry requirements for continuous monitoring. With the ability to analyze 15+ chemicals per sample point, the MAX300-TGM toxic gas analyzer provides maximum efficiency at an extremely low cost-per-chemical, per sample point.

Make false alarms a thing of the past with this interference-free solution. Our EXTREL products have been an industry leader in user-friendly mass spectrometry for over 60 years. This expertise is applied to the MAX300-TGM toxic gas analyzer with rigorous testing for common interferences across chemical spectrums. The platform then removes unwanted effects, providing a reliable analysis.

Industry leading expertise is also applied to its intuitive, user-friendly software which is designed for at-a-glance operation. The platform’s versatility and configurability make integration straightforward. The analyzer is equipped with standard operation templates that can be fully customized to meet site requirements for:

-

-

- Order of sample points

- Frequency of sample points

- Alarm Levels (Level 1 and Level 2)

- Enabling or disabling sample points

- Addition or removal of chemicals

- Addition or removal of sample points

- Field upgradeable to 46 sample points

-

This centralized gas monitoring solution streamlines maintenance. Gone are the days of visiting hundreds or thousands of locations and maintaining single gas sensors. Modularized, plug-and- play components for maintenance provide >99% uptime and fast maintenance routines. Built in redundancy for critical components maximizes uptime allowing the site to stick to pre-defined maintenance plans.

Key Features

-

-

- Detect more than 15 chemicals on up to 46 sample points

- Analysis speed of 0.4 seconds per chemical

- Fully customizable to meet site requirements

- Low cost of ownership and streamlined operation

- Automated performance checks during operation

- Plug-and-play critical modules to reduce downtime

- Pre-defined preventative maintenance schedule

- Redundant:

-

-

- Sample pumps

- Secondary ionizer filament

- Alarm verifications

-

-

- At-a-glance alarm indications for Level 1 and Level 2 conditions

- “Revisit” sample points in alarm while continuing monitoring sequence

- Alarms are easily integrated into facility management systems

- Remote access capable

-

INDUSTRIES

-

-

- Semiconductor

- Chemical and Industrial Sites

- Petrochemical

- Pharmaceutical

-

SAMPLING CONFIGURATION – 16 to 46 points

The speed of the MAX300-TGM toxic gas analyzer allows one analyzer to monitor sample points spread throughout the site without sacrificing fast updates. Two integrated oil-free sample pumps can be operated together or for redundancy. Rotary valve options include 16, 31, or 46 ports. Field upgrade options are available.

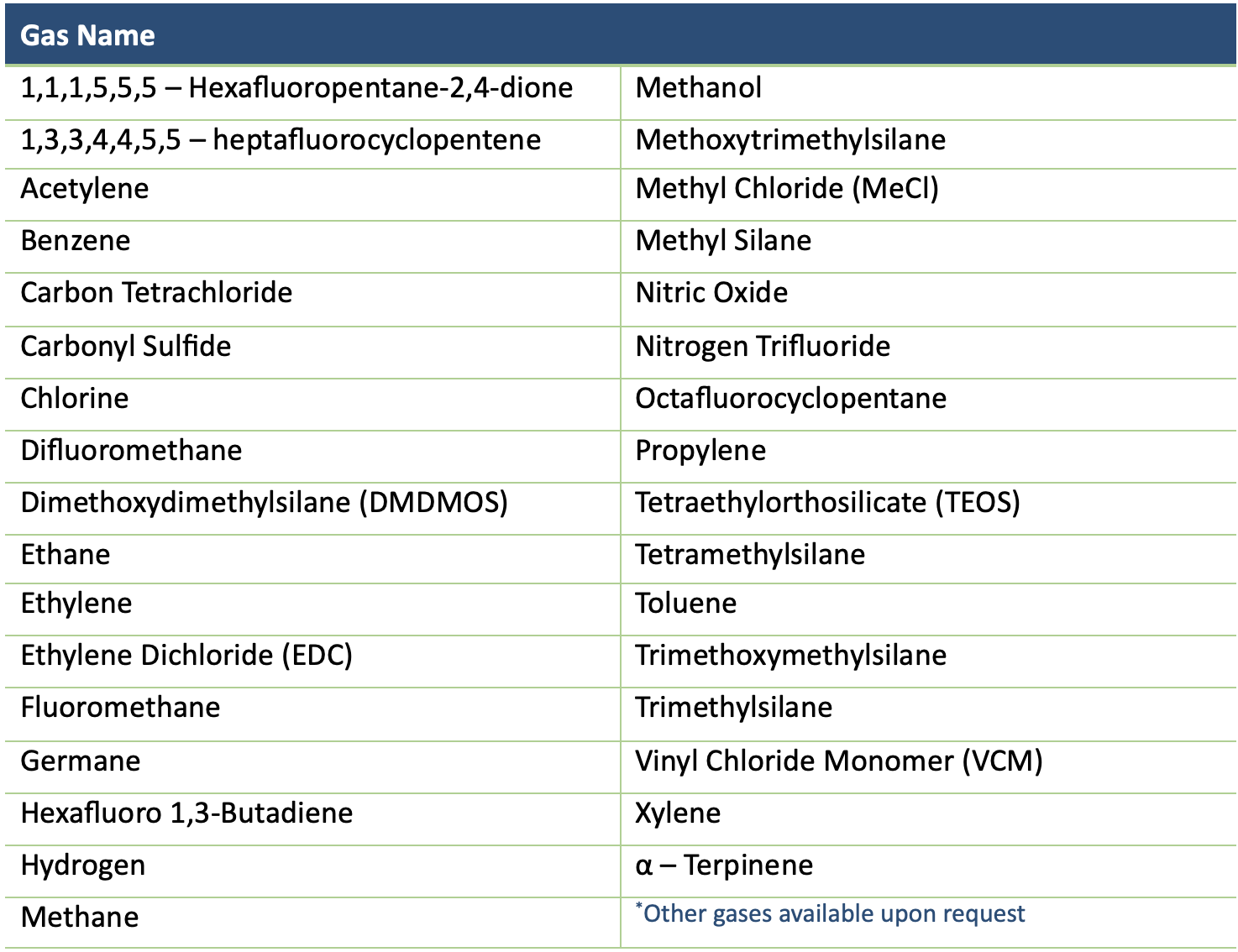

Partial list of detectable Gases*

Real-Time Analyzer for Air and

Environmental Monitoring Applications

Environmental Monitoring Applications

Need help with an application? Complete our Mass Spectrometer Application Questionnaire.

|

Need a monitoring solution for hazardous areas? Click here to learn more about our MAX300-AIR Quadrupole Mass Spectrometer |

61010-1

Solutions Flyers

-

AGRICULTURE

-

CHEMICAL

-

ENERGY

-

FOOD & BEVERAGE

-

FLARE GAS

-

INDUSTRIAL GAS

-

LAB & RESEARCH

-

PHARMACEUTICALS & LIFE SCIENCE

-

REFINERY

-

SEMICONDUCTOR

-

SPECIALTY GAS