Semiconductor

ANALYTICAL SOLUTIONS FOR High Purity

RELIABLE GAS ANALYSIS SOLUTIONS FOR Gas Quality Control & Safety Monitoring For Semiconductor Fabs

Semiconductors are considered the brains of modern electronics. Our TIGER OPTICS™ Cavity Ring-Down Spectroscopy (CRDS) gas analyzers seamlessly detect parts-per-billion (ppb) and parts-per-trillion (ppt) levels and delivers bulk gas monitoring for trace H2, H2O, O2, CH4, CO, CO2, Kr, NH3, and Xe, UHP ammonia for HB LED production, tool monitoring for trace H2O and HF, and continuous AMC monitoring for ambient HCl, HF, and NH3.

Specialty gases of superior quality play a vital role as raw materials and process gases across various industries. From carbon dioxide in beverages to ammonia in LED manufacturing and silane in semiconductor fabrication, maintaining high purity standards for specialty gases is critical. The presence of moisture impurities, for instance, can significantly impact the efficiency of resulting LEDs. The semiconductor industry demands ultra-high purity gases, whether it’s silane or germane for epitaxy, fluorine compounds for etching processes, or cleaning gases. Process Insights offers highly sensitive, accurate, and user-friendly analysis instruments. These instruments utilize the renowned Cavity Ring-Down Spectroscopy (CRDS) technique and cater to a wide range of specialty gases and applications.

We know your process and how critical it is for you to protect precious and limited resources. Get the most reliable, most precise gas analysis technologies available on the market today. We will work to match your needs and budget and provide the optimal, and most stable process analysis solution for your application.

For a complete range of analytical instrumentation, applications, systems, and service options, we will work to match your needs and budget and provide the optimal, and most stable process analysis solution for your application.

SALES | TRAINING INQUIRIES

AMERICAS: info@process-insights.com

EMEAI: info.emeai@process-insights.com

APAC: info.apac@process-insights.com

CHINA: info.cn@process-insights.com

SERVICE | TECHNICAL INQUIRIES

FEATURED PRODUCTS

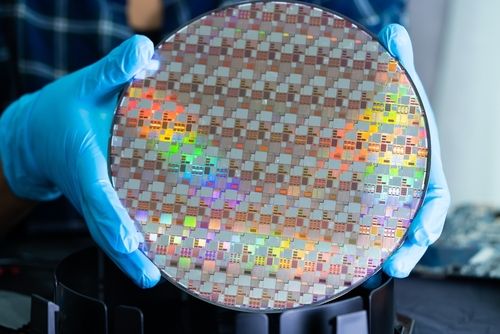

CONTINUOUS QUALITY CONTROL (CQC) IN THE SEMICONDUCTOR INDUSTRY

Cavity Ring-Down Spectroscopy (CRDS) gas analyzers from Process Insights have a long history in industrial gas, medical gas, and chemical processing, enabling the detection of moisture and other rogue impurities in process gas streams, including inert, reactive, corrosive, bulk, and specialty gases.

Cavity Ring-Down Spectroscopy (CRDS) Technology delivers a highly sensitive and precise analytical technique used for the detection and measurement of trace gases and isotopes in a sample. It is a non-destructive technique that provides quantitative measurements of molecular absorption spectra.

- Offers multiple technology choices to meet all customer needs

- Expert team who understands and supports all UHP and semiconductor applications IQC/OQC/CQC

- Delivers both pre- and post-purifier trace impurity measurements

- 1-year warranty on all analyzers and cabinets

- 2-years of on-site service and spare parts

CQC MONITORING SOLUTIONS AVAILABLE

- Cavity Ring-Down Spectroscopy (CRDS)

- Atmospheric Pressure Ion Mobility Spectrometry (APIMS)

Simultaneously Monitor HF, HCl, and NH3 in Real-Time

T-I MAX X2_X3 AMC MONITORING SOLUTION

Next-Generation Trace Gas Analyzers for Detection & Continuous Monitoring of Airborne Molecular Contaminants in Semiconductor Cleanrooms, FOUP Cleaning Tools, Reticle Nests and Sub Fab Environments. You can spend a long time “looking” for Airborne Molecular Contaminants (AMCs) when the catastrophic product performance or yield loss is discovered at your device final test stage; or you can deploy our T-I Max™ series analyzers to locate and to monitor these invisible defect generators, commonly found lurking in and around equipment, personnel, wafer carriers and cleanroom bays.

MAX300-TGM™

Real-Time Toxic Gas Monitoring Solution in Ambient Air

Our NEW MAX300-TGM™ Toxic Gas Monitor is a real time monitoring solution with analysis speeds of 0.4 seconds per chemical and gas clearing times of less than 3 seconds. These impressive speeds exceed industry requirements for continuous monitoring. With the ability to analyze 15+ chemicals per sample point, the MAX300-TGM toxic gas analyzer provides maximum efficiency at an extremely low cost-per-chemical, per sample point.

MAX300-TGM Advantages Include:

- Versatile and flexible analyzer – detect multiple chemicals on up to 46 sample points

- Fast measurement with high sensitivity, reducing false alarms

- Highly responsive to changes in chemical concentration – reducing down time after an event

- Streamlined operation – centralized analyzer for full facility monitoring

- Low cost of ownership and streamlined operation – decreasing complexity in maintenance and upkeep

- Industry leading application expertise and technical support with decades of experience with ambient air monitoring

- Large, user-friendly touch screen interface for at-a-glance updates with customizable alarm verifications

VeraSpec™ APIMS

Semiconductor manufacturers need the ability to continuously verify the purity of process gases in real-time and detect trace contamination at concentrations in the low parts-per-trillion (ppt). Monitor a wide range of gases and gas mixtures with the stability that provides the long-term repeatability required in most applications.

Our VeraSpec™ Atmospheric Pressure Ionization Mass Spectrometer (APIMS) is designed for reliable and repeatable low parts-per-trillion detection limits for contamination control in Ultra-High Purity (UHP) gases used in semiconductor and other high-tech industrial applications.

VerSpec APIMS Benefits Include:

- Industry-best lower detection limits (LDLs) for bulk gas analysis

- Real-time, multi-species monitoring for ALL critical Impurities in bulk gases including trace O2, H2, H2O, CH4, CO, CO2, Xe and more

- Well-established, powerful mass spectrometry technology

- Unparalleled measurement range from PPT to 100% with unique dual-source ionization configuration

HALO™ KA Max

Compact and affordable while giving you moisture impurity levels down to 100 ppt in helium, with drift-free stability and virtually instant response.

It offers exceptional speed and further improved usability in an all-inclusive and compact form factor. The analyzer is fast to install, easy to use and effortless to maintain, with built-in zero verification.

- Parts per trillion (ppt) moisture detection capability in an array of gases

- Absolute measurement (freedom from calibration)

- Field proven lowest Cost of Ownership and ease of use

- Wide dynamic range—over four orders of magnitude

- Unprecedented speed of response at sub-ppb H2O levels

- Compact footprint (two Halo KA Max fit in a 19” rack)

A Cost-Effective Mobile Solution

Our mobile GO-cart is easy to move around the fab and comes with the following features:

- Space for up to three T-I Max analyzers with low-power, fanless vacuum pumps

- No calibration, maintenance or consumables required (for both cart and analyzers)

- Top-mounted central control touchscreen

- Integrated UPS backup power supply (optional)

- Conductive ESD paint (optional)

-

AIRBORNE MOLECULAR CONTAMINANTS

Airborne molecular contamination (AMC) impacts semiconductor fabs and cleanrooms. It is sometimes referred to as chemical contamination. Every material introduced into a cleanroom is a potential source of airborne molecular contamination (AMC). AMC can cause changes in a wafer’s electrical properties at the parts-per-trillion (ppt) level in air. This contamination must be taken very seriously. Volatile Organic Compounds (VOC) are present even in clean production environments. Airborne contaminants reduce yield-quality, impact tools, and are costly when not monitored.

Our solutions also include:

- Continuous AMC monitoring ppt-Level in Clean Room Air T-I Max HCI and T-I Max NH3 and T-I Max HF

- Mobile Solution for Monitoring AMC GO-Cart™

MULTI-MAX AMC MONITORING SOLUTION

You can spend a long time looking for Airborne Molecular Contaminants (AMCs) when the catastrophic product performance or yield loss is discovered at your device final test stage; or you can deploy our Multi-Max AMC to locate and to monitor these invisible defect generators, commonly found lurking in and around equipment, personnel, wafer carriers, and cleanroom bays.

In today’s advanced semiconductor processing, the residual gases, vapors and chemicals emanating from the various materials, accelerated processing operations, and substrate storage and transport have become a critical concern. The International Technology Roadmap for Semiconductors (ITRS) now highlights AMC contamination as a key technical challenge in achieving and sustaining low defect rates on devices.

-

ELECTRONIC GAS

Electronic gases and semiconductor gases are process gases used in electronic manufacturing. The electronic gases include pure gases and gas mixtures which are specially configured for specific manufacturing processes. Electronics gases must be high purity gases. Precise gas delivery is at the core of semiconductor fabrication.

Our TIGER OPTICS™ Cavity Ring-Down Spectroscopy trace gas analyzers have supported the semiconductor industry and other micro-electronic manufacturing sectors. Based on their superior sensitivity, great stability and unparalleled uptime, and free of periodic maintenance, with no moving parts or consumables they are the ideal choice for semiconductor fabs. SEMI F-112 designates CRDS as the standard in determining moisture dry-down characteristics of ultra-high-purity gases and their respective delivery systems.

Our solutions also include:

- Bulk gas monitoring for trace H2, H2O, O2, CH4, CO, CO2, Kr, NH3, and Xe

- Real-Time, ppt-Level, Multi-Impurity Analysis EXTREL™ VeraSpec™ APIMS

- CRDS Trace Gas Analyzer for O2 HALO OK™

- CRDS For ppt-Level H2O, CH4 and NH3 HALO KA Max™

- ppt-Level CRDS for CO and CO2, HALO Max QCL™

- CRDS for Pre-Purifier Measurement H2O, CH4, CO, CO2, C2H2 Spark™

-

LAB, SAFETY & COMPLIANCE

Many hazards can occur in semiconductor fabrication (fab) and laboratories. Semiconductor Equipment and Materials International (SEMI) standards exist for process liquid heating systems, sizing and identifying flow, devices for gas cylinder valves, equipment safety labeling, exhaust ventilation, ergonomics engineering for equipment, and risk assessment. For instance, moving specialty gas cylinders should be accompanied by periodic leak testing. Also, the Semiconductor Industry Association has taken a proactive stance on improving safety across the semiconductor manufacturing process as well as protecting employees. Our solutions support a safe environment plus adhere to health and safety (EHS) standards across all of our semiconductor fabrication.

Our solutions also include:

- Trace to Percent Oxygen Monitors for Portable and Fixed Applications ALPHA OMEGA INSTRUMENTS™ Series 1300™ and OXY-SEN™

- Aluminum Oxide Dew Point Meters & Transmitters with Hyper-Thin-Film Technology for Portable/Fixed/Loop-Powered Applications COSA XENTAUR™ XDT™| XPDM™ | LPDT2™

- CRDS Trace Gas Analyzer for ppb-Level Detection of H2O, CH4, CO, CO2and C2H2 Spark™

- Benchtop Mass Spectrometers for Real-Time, ppb-level, Multi-Impurity Analysis EXTREL™MAX300-LG™

- Ambient Air Mass Spectrometer for Environmental Applications EXTREL™ MAX300-AIR™

- Chilled Mirror Dew Point Meter and Humidity Generators MBW™ Model 473™

-

LITHOGRAPHY

Vacuum Ultraviolet (VUV) lithography is a process used in semiconductor manufacturing to create tiny features on semiconductor wafers using extreme ultraviolet light. Quadrupole mass spectrometers can be used in VUV lithography to monitor the purity of gases used in the lithography process.

By monitoring the gas purity with a quadrupole mass spectrometer, VUV lithography manufacturers can quickly detect any impurities that may be present in the gas stream and take corrective action to ensure the quality of the lithography process. This can help to improve the yield and quality of the final semiconductor product.

-

MOLECULAR BEAM EPITAXY (MBE) MONITORING

Molecular Beam Epitaxy (MBE) is a technique used in materials science and semiconductor device fabrication to grow thin films of various materials with extremely precise control over thickness and composition. MBE is a type of vapor deposition process, in which the materials are evaporated in a vacuum chamber and deposited onto a substrate, typically a single crystal wafer, to create a thin film.

Our EXTREL™ Quadrupole Mass Spectrometer are commonly used in Molecular Beam Epitaxy (MBE) to monitor and control the quality of the deposited films. The high vacuum environment of the MBE chamber, along with the controlled deposition rate and composition, ensure that the deposited films have high purity and are free from contamination. However, it is still important to monitor the gas-phase environment in the MBE chamber during the deposition process to ensure that the deposited films have the desired composition and properties. This is where quadrupole mass spectrometry comes into play.

-

PROCESS CONTROL

It’s one thing to be monitoring and have high confidence in your high purity bulk and specialty gases at the post-purifier stage but a lot can change as that same gas then travels through the various fab distribution systems and arrives at the equipment or process chamber. Unless you are monitoring close to the substrate or in the process chamber exhaust, there is risk that high partial pressures of moisture are present during processing, resulting in defects causing yield loss and reliability issues.

Hydrogen fluoride is essential to the semiconductor process. Able to operate in a pressure range from 50 Torr to 15 psig, the TIGER OPTICS™ HALO™ RP trace level analyzer provides users with the unmatched accuracy, reliability, speed of response and ease of operation. The Halo RP is available for two different analytes, H2O and HF, to ensure that your product is protected from all harmful molecules. Ideal for gas quality control, research & development, semiconductor process tools, and UHP ammonia and high-brightness LED.

Our solutions also include:

- Aluminum Oxide Dew Point Meters for Portable/Fixed/Loop-Powered Applications COSA XENTAUR™ XDT™/ XPDM™/ LPDT2™

- Mass Spectrometer for Real-Time, ppb-Level Analysis EXTREL™ MAX300-LG™

- CRDS Trace-Level, Low-Pressure Moisture Analyzer TIGER OPTICS™ HALO QRP™

- CRDS Reduced-Pressure, Trace-Level Analyzer TIGER OPTICS™ HALO RP™

-

PLASMA AND CVD PROCESS MONITORING

Plasma Etch, Chemical Vapor Deposition (CVD) and Plasma-Enhanced Chemical Vapor Deposition (PECVD) applications require a thorough understanding of the complex chemistries involved in the processes. Also critical to the processes is the ability to monitor low-level components.

Our EXTREL™ Quadrupole Mass Spectrometer can be used in PECVD to monitor the gas-phase environment in the plasma reactor during the deposition process. This is important because the gas-phase environment can affect the composition and quality of the deposited thin films. By measuring the partial pressure of various gases in the plasma reactor, the quadrupole mass spectrometer can provide information on the composition of the gas-phase environment and can be used to adjust the deposition conditions to ensure the desired film properties.

-

SCRUBBER / BURN BOX EFFICIENCY

In the semiconductor industry, scrubbers and burn boxes are used to safely dispose of hazardous gases used in the manufacturing process, such as chlorinated and fluorinated gases. Scrubber and burn box efficiency are important for meeting regulatory requirements and ensuring the safety of workers and the environment. Regular monitoring and maintenance of scrubbers and burn boxes are necessary to ensure their efficiency and effectiveness in removing hazardous gases.

Our EXTREL™ MAX300-RTG™ 2.0 Process Gas Analysis Mass Spectrometer and the MAX300-LG™ Laboratory Gas Analysis Mass Spectrometer offer analysis from 100% down to 10 parts per billion (ppb) with unmatched accuracy and repeatability. Our systems are used to aid the effort to reduce emissions and ensure compliance with applicable regulations is to monitor the efficiency of abatement systems.

-

SPECIALTY GASES

Specialty gases are used across many applications in the semiconductor chip manufacturing process. Specialty gases for the semiconductor manufacturing include industrial gases, ammonia, methane, fluorinated compounds and sulfur hexafluoride. Electronic process gases must be manufactured, used, and tested based on various standards.

Based upon our CRDS gas analyzer performance, the SEMI F-112 standard calls out CRDS as the technology of choice in determining moisture dry-down characteristics of high-purity gas systems. To check incoming or point-of-use quality, our CRDS analyzers monitor for O2, H2O, CH4, CO, CO2 and more down to parts-per-billion (ppb) and even parts-per-trillion (ppt) levels. A special low-pressure version, our TIGER OPTICS™ Cavity Ring-Down Spectroscopy HALO™ LP monitors for impurities in hydrides, including arsine, phosphine and ammonia.

If low-ppb moisture measurement in pure ammonia is required, our ALOHA+ H2O specializes in this application. Our CRDS analyzer portfolio delivers bulk gas monitoring for trace H2, H2O, O2, C4, CO, CO2, Kr, N3, and Xe, UHP ammonia for HB LED production, tool monitoring for trace H2O and HF, and continuous AMC monitoring for ambient HCl, HF, and NH3.

Our solutions also include:

- Aluminum Oxide Dew Point Meters for Portable/Fixed/Loop-Powered Applications COSA XENTAUR™ XDT™/ XPDM™ / LPDT2™

- ppt-Level CRDS Trace Moisture Analyzer TIGER OPTICS™ HALO KA H2O™

- CRDS for Corrosive, Rare, and Fluorinated Gases TIGER OPTICS™ HALO3™

- CRDS for ppt-Level H2O in pure NH3 TIGER OPTICS™ALOHA+ H2O™

-

ULTRA-PURE WATER

In the semiconductor industry numerous processes need ultra-pure water for their operation. Any disturbance in water quality may lead to a cost intensive plant shut down – this should be avoided. Therefore, continuous and fast water analysis is required to meet the high-quality standards set.

The high quality and purity requirements for product and process safety are met by accurate and reliable online TOC water quality monitoring in the lowest levels. Ultra-pure water is prepared under particularly stringent specifications. It is a matter of ensuring purity in respect of all types of contaminants: organic/inorganic compounds, dissolved/solid or volatile/non-volatile components, dissolved gases, reactive/inert substances etc. Depending on the respective application, requirements regarding UPW purity are defined in norms such as ASTM D5127 and SEMI F63.

Explore more Wastewater & Ultra-Pure Water in Semiconductor Mfg

Our solutions include:

- TOC Water Analyzer for Harsh Wastewater Applications LAR™ QuickTOCultra™

- TOC Water Analyzer for Clean Water Applications LAR™ QuickTOCuvll™

- TOC Water Analyzer for Municipal & Cooling Water Applications LAR™ QuickTOCeco™

- COD Water Analyzer for Laboratories LAR™ QuickTOClab™

-

WASTEWATER

In the semiconductor industry numerous processes need ultra-pure water for their operation. Any disturbance in water quality may lead to a cost intensive plant shut down – this should be avoided. Therefore, continuous and fast water analysis is required to meet the high-quality standards set.

The high quality and purity requirements for product and process safety are met by accurate and reliable online TOC water quality monitoring in the lowest levels. Ultra-pure water is prepared under particularly stringent specifications. It is a matter of ensuring purity in respect of all types of contaminants: organic/inorganic compounds, dissolved/solid or volatile/non-volatile components, dissolved gases, reactive/inert substances etc. Depending on the respective application, requirements regarding UPW purity are defined in norms such as ASTM D5127 and SEMI F63.

Explore more Wastewater & Ultra-Pure Water in Semiconductor Mfg

Our solutions include:

- TOC Water Analyzer for Harsh Wastewater Applications LAR™ QuickTOCultra™

- TOC Water Analyzer for Clean Water Applications LAR™ QuickTOCuvll™

- TOC Water Analyzer for Municipal & Cooling Water Applications LAR™ QuickTOCeco™

- COD Water Analyzer for Laboratories LAR™ QuickTOClab™