Model 373

High Performance for Humidity Measurements

For Mission Critical Industries – ANALYZE WITH EASE™

Our MBW CALIBRATION™ MODEL 373™ Dew Point Chilled Mirror Analyzer has been measuring humidity for almost 20 years. Incremental development based on operational experience and customer feedback means that the 373 continues to exceed the expectations of hundreds of users in some of the most challenging humidity applications and mission critical industries. Despite its high performance and specification, the 373 is easy to use and simple to maintain. The touch panel user interface is simple and intuitive to use and enables even inexperienced users to perform measurements successfully. Even early instruments remain serviceable thanks to the use of industry standard components and careful control of software build records.

A unique feature of the MODEL 373 Dew Point Chilled Mirror Analyzer is its dual mirror PRT configuration. In standards laboratories, this means that the user can use an external resistance bridge to measure the mirror temperature independent of its electronics so that measurement uncertainty can be reduced, and long-term stability maintained in the event of changes to any of its measurement electronics. The latest developments include improved materials of construction to further reduce sorption effects, higher pressure capability based on new measuring head designs, data acquisition software with automated humidity generator control, and multichannel thermometer data integration.

BENEFITS

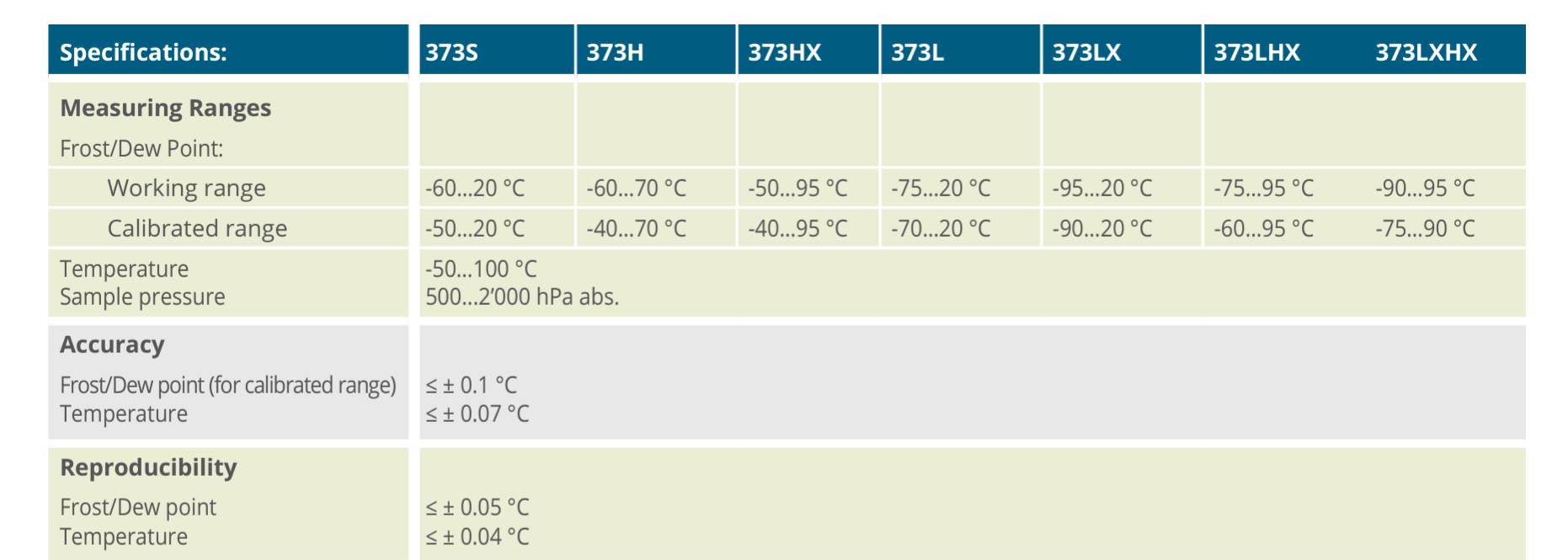

- High accuracy: Uses the chilled mirror technique to measure dew point temperature, which is considered to be the most accurate method for measuring humidity. The instrument provides high accuracy and repeatability, with a measurement uncertainty of ±0.1°C.

- Wide measurement range: Can measure dew point temperatures from -100°C to +20°C, making it suitable for a wide range of applications. It can also measure frost point temperatures down to -90°C.

- Fast response time: Provides fast response times, with a typical response time of 5 minutes for a 90% step change in humidity. This allows for real-time monitoring and control of humidity levels in various applications.

- User-friendly interface: Features a user-friendly interface with a large, easy-to-read display and intuitive menus. The instrument can be operated with just a few buttons, and it provides on-screen prompts to guide the user through the measurement process.

- Low maintenance: Designed for easy maintenance, with a simple mirror cleaning process that can be done quickly and easily. The instrument also features a self-diagnostic function that alerts the user to any issues that may require attention.

- Robust design: Built to withstand harsh environments and can be used in a wide range of applications. It features a rugged, portable design with a protective carrying case, making it easy to transport between locations.

- Traceability: Is traceable to national standards, providing assurance of the accuracy and reliability of the measurements. The instrument also features a built-in data logging function, allowing for easy record-keeping and documentation of the measurements.

INDUSTRIES

- Semiconductor manufacturing: Used in semiconductor manufacturing processes, where precise control of humidity levels is critical for ensuring the quality and reliability of the final product. The instrument is used to monitor and control humidity levels in cleanroom environments, as well as in the manufacturing process itself.

- Pharmaceutical manufacturing: Used in pharmaceutical manufacturing processes, where accurate humidity control is necessary for ensuring product quality and safety. The instrument is used to monitor and control humidity levels in production areas, as well as in storage and transportation environments.

- Petrochemical industry: Used in the petrochemical industry for monitoring and controlling humidity levels in various processes, such as natural gas production, refining, and storage. The instrument is used to prevent corrosion and ensure the safe and efficient operation of equipment.

- Power generation: Used in power generation facilities to monitor and control humidity levels in various processes, such as combustion control and turbine inlet air conditioning. The instrument is used to optimize efficiency and reduce maintenance costs.

- Environmental monitoring: Used in environmental monitoring applications, such as weather stations and atmospheric research. The instrument is used to measure dew point and other humidity-related parameters in the atmosphere, which is important for understanding weather patterns and climate change.

- Calibration laboratories: Used in calibration laboratories for calibrating other humidity measurement instruments. The instrument’s high accuracy and traceability to national standards make it a reliable reference instrument for calibration purposes.

Do you have a MBW instrument?

Do you need technical support?

Open a ticket.

Do you have a MBW instrument?

Do you need technical support?

Open a ticket.

Need help? Complete our Water Vapor

Application Questionnaire.

Services

- Service and Repair

- Calibration

- On Site Service, Repair and Calibration

- 17025 Calibration

- SCS Calibration Laboratory

- DAkkS Calibration Laboratory

- Calibration of non-MBW products

- Training

- Consulting

- Gecko R2 Software for data acquisition and display

WHEN YOU NEED CLIMATIC CHAMBER VALIDATION

Climatic chambers are in widespread use across many industries. They are used to simulate climatic conditions including temperature, humidity, pressure, vibration and light intensity. Conditions are controlled or varied according to user or test specifications. Products and samples are placed within the controlled environment according to defined test specifications that require certain conditions to be maintained. Examples include 40 °C / 75 %rh for drug stability and 85 °C / 85 %rh for electronic component testing. Confirmation that the correct environmental conditions have been achieved is a pre-requisite for compliance with the respective standards that apply in each industry.

SOLUTIONS FLYERS

-

AGRICULTURE

-

CHEMICAL

-

ENERGY

-

FOOD & BEVERAGE

-

FLARE GAS

-

INDUSTRIAL GAS

-

LAB & RESEARCH

-

PHARMACEUTICALS & LIFE SCIENCE

-

REFINERY

-

SEMICONDUCTOR

-

SPECIALTY GAS