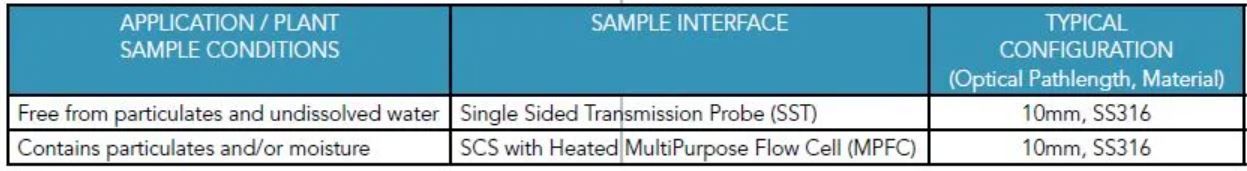

Ou GUIDED WEAVE probes and flow cells offer high throughput, collimated optical beams through the sample, yielding lower noise and more accurate transmission values free of sample index of refraction effects. For faster maintenance and cleaning of insertion probes, the Extractor Mechanism can be used. The controlled extraction of an in-line probe from pressurized process streams or reactors can be accomplished without shutting down the process, allowing continued use of the analyzer to verify process quality. Coupled with a gate or ball valve, these extractors have proven safe and effective in a variety of refinery installations such as Reformer, Gasoline Blending, Blender and Feed Streams saving downtime. James Low, Guided Wave’s Director of Sales and Support states, “The SST insertion probe extractor assembly is worth every penny when you consider the time saved on insertion probe maintenance.” He continues, “I’ve been using Guided Wave products almost since its beginning and the SST probe and the multipurpose flow cell are extremely durable and reliable. Our probes and flow cells are compatible with nearly every brand of analyzer and in normal refinery use they function virtually forever”.