Styrene, Acrylonitrile & Methyl-ethyl-ketone (MEK)

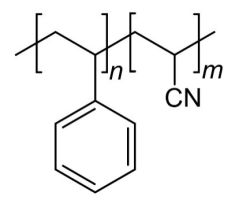

Styrene acrylonitrile resin, known as SAN, is a copolymer plastic consisting of styrene and acrylonitrile. Due to its superior thermal resistance, it is widely used in place of polystyrene. By weight the relative composition is usually 70-80% styrene and 20-30% acrylonitrile. Mechanical properties and chemical resistance of SAN can be improved with a larger acrylonitrile content, but the compromise is a yellow tint to the normally transparent plastic. Product from this plastics family includes food containers, water bottles, kitchenware, computer products, packaging material, battery cases and plastic optical fibers. Styrene gives the plastic a nice glossy finish. Styrene revenue is projected to increase at a compound annual growth rate (CAGR) of over 9% from 2019 to 2025, according to the Global Newswire network. They report an increased demand in the manufacture of various products, using acrylonitrile butadiene styrene (ABS), expanded polystyrene, and polystyrene as the contributing factors.

Controlling the product properties can be a challenging task for process engineers in the polymer industry. Near-infrared (NIR) spectroscopy is a convenient and cost-effective tool for monitoring reaction processes in situ to ensure that the correct chemical ratios, average molecular weight, and physical properties are within specifications. When transparency is a concern, the process engineer has several options. If polystyrene’s mechanical properties are insufficient, the process engineer can tailor a specific formulation of styrene-acrylonitrile copolymers or SANs (Figures 1 and 2). These copolymers typically contain between 20–30% acrylonitrile. Due to the polar structure of acrylonitrile, SANs copolymers have better resistance to breakdown in hydrocarbon streams than polystyrene. SAN copolymers also have a higher softening point, rigidity, and impact strength, yet maintain their transparency.

As the acrylonitrile content of the SAN copolymer is increased, there is an improvement in the toughness and chemical resistance. The trade-off is a greater difficulty in molding and potential yellowness of the resin. SANs copolymers are also used in polyols processing to strengthen other polymer types. Monitoring stream composition during processing allows manufacturers to maintain product quality.

By incorporating a near-infrared (NIR) spectrometer and in situ process probe, a process engineer can quickly identify when the mixture of component concentrations are out of specification. The NIR region of the electromagnetic spectrum measures the overtone and combination bands of the C-H, O-H, and N-H fundamentals absorption bands. These spectra are unique to the molecule thus permitting the process engineer to make real-time corrections and ensure that product quality is maintained. In the case of SANs, NIR spectroscopy can be used to monitor the concentration of Styrene, Acrylonitrile, and MEK molecules

Today the use of DG-NIR analyzers continues to improve the accuracy and speed of measurements for polymer feed concentrations that can be achieved with our analyzers; the NIR-O full spectrum NIR analyzer or the ClearView db photometer. By collecting these data, process engineers in the polymer plant can make informed decisions on process optimization to ensure product quality.

Our comprehensive GUIDED WAVE NIR UV-VIS process and lab analyzer spectrometers offer optically matched components and a meticulously planned calibration approach, ensuring long-term efficiency and cost savings. Our advanced systems are engineered for continuous online operation, delivering real-time data of laboratory-grade quality, even in the harshest processing plant conditions.