Cavity Ring-Down Spectroscopy Technology

Cavity Ring-Down Spectroscopy (CRDS) Technology

Cavity Ring-Down Spectroscopy (CRDS) technology is a highly sensitive and precise analytical technique used for the detection and measurement of trace gases and isotopes in a sample. It is a non-destructive technique that provides quantitative measurements of molecular absorption spectra.

The CRDS technology works by measuring the rate at which light is absorbed by a gas sample contained in a highly reflective cavity. A laser pulse is introduced into the cavity, and the light bounces back and forth between two highly reflective mirrors at the ends of the cavity. As the light bounces back and forth, it is absorbed by the gas sample in the cavity, causing a gradual decrease in the intensity of the light. The time it takes for the light to decay or “ring down” to a predetermined threshold level is measured, and this decay time provides information on the concentration of the gas species in the sample.

CRDS technology is highly sensitive, capable of detecting trace levels of gases and isotopes at parts-per-billion (ppb) or parts-per-trillion (ppt) concentrations. It is also highly selective, allowing the measurement of specific gas species and isotopes in a complex gas mixture.

A breakthrough discovery by Professor Kevin Lehmann, Ph.D., of Princeton University made the commercialization of this technique possible. He proved that compact, relatively inexpensive, and widely available Continuous Wave (CW) lasers can substitute for the costly, cumbersome pulsed lasers previously used in CRDS-based research. He thereby made the requisite power of light affordable and practical for commercial use. Based on absorption spectroscopy, our TIGER OPTICS™ Cavity Ring-Down Spectroscopy (CRDS) works by attuning light rays to the unique molecular fingerprint of the sample species. By measuring the time, it takes the light to fade or “ring-down”, you receive an accurate molecular count in milliseconds. The time of light decay, in essence, provides an exact, non-invasive, and rapid means to detect contaminants in the air, in gases, and even in the breath.

In 2001, our CRDS gas analyzers were the first commercial Cavity Ring-Down Spectroscopy (CRDS) analyzers available on the market. Today, our CRDS gas analyzers monitor thousands of critical points for industrial and scientific applications. They serve the world’s national metrology institutes, where they function as transfer standards for the qualification of calibration and zero gases.

Cavity Ring Down

Spectroscopy Technology

Cavity Ring Down

Spectroscopy Technology

PRINCIPLE OF CRDS TECHNOLOGY

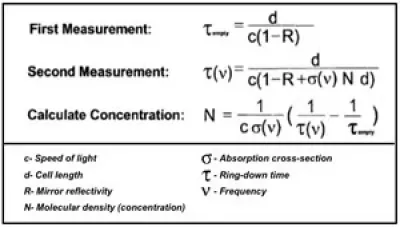

- The computer-controlled system tunes the laser off the absorption peak for the sample species to determine the τ empty value, equivalent to a zero-baseline correction.

- It tunes back to the absorption peak to determine the τ value, dependent on the sample species concentration.

- The concentration of the sample species is directly calculated using the above equations.

- Based on Beer’s Law, this value constitutes an absolute measurement and is unaffected by losses outside the ring-down cavity.

KEY COMPONENTS of CRDS Technology

- Diode laser or QCL: Emits near-IR or mid-IR light

- Isolator: Prevents light energy feedback from interfering with the laser

- Acousto-optic Modulator (AOM), optional: Shuttering device for the light source

- Absorption cell with mirrors: Creates optical cavity where the gas is measured

- Photodiode: Monitors the light energy from the cavity

- Trigger: Works in concert with the photodiode and sends signal to the AOM or another shuttering device to start the ring-down event.

RING DOWN/ EXPONENTIAL DECAY

This graph depicts the concept of ring-down decay within the cavity after the laser source is shuttered. As the laser light bounces back and forth between the ultra-high reflective mirrors, the sample species absorbs the light energy until it’s all gone.