Analyze HPLC Binary Solvent Feed Mixtures

Analyze HPLC Binary Solvent Feed Mixtures

Binary solvent mixtures are used as carriers in production scale pharmaceutical HPLC separations. Analysis of the mixture ratios is required prior to injection into the HPLC column. The correct mixture ratio ensures efficient and correct separation of the chemical targeted for separation. Concentrations of individual solvents can be measured over the entire range from 0 to 100%. Traditionally these analyses are made using laboratory methods or online conductivity. Laboratory methods are typically time consuming and costly. Online conductivity suffers from an inability to measure some of the binary mixtures accurately.

For more than three decades, near infrared (NIR) spectroscopy has been used to measure composition in a wide variety of chemical, petrochemical, and agricultural applications. NIR technology, equipment, software, and methods are quite mature and sophisticated. Our GUIDED WAVE™ NIR analyzers and software have been installed across the chemical industry for more than 20 years, pioneering the use of fiber optic coupled spectrometers for in-line process spectroscopy. As a result of our experience, we were asked to undertake an application study to demonstrate our capability to perform fast, online analysis of HPLC Binary Solvent Feed Mixtures. We chose to measure the concentration ratios of two different mixtures:

1) Heptane / Ethyl Acetate

2) Methylene Chloride / Ethyl Acetate

Online measurement of the composition of solvent mixtures is conveniently done using NIR spectroscopy. This technique is ideal for measuring clear liquids online since the analyzer can be remotely located and connected to a flow cell or in-line probe via fiber optic cables. This remote measurement capability makes NIR an excellent choice for measurements on flammable or explosive liquids, minimizing both exposure and safety risks. Guided Wave NIR spectrometers have excellent signal-to-noise ratios, superb long term stability, multi-channel capability and provide fast and reliable results.

The application demonstrations described here involve binary mixtures of heptane / ethyl acetate and methylene chloride / ethyl acetate. These are just two examples of binary solvent mixtures frequently used in preparative scale HPLC separation.

Analysis and Results – HPLC Binary Solvent Feed Mixtures

NIR Spectra of Heptane Ethyl Acetate Mixtures

NIR Spectra of Methylene Chloride Ethyl Acetate Mixtures

SALES | TRAINING | SERVICE

Americas +1.916.638.4944

EMEA +49 69 20436910

China/APAC +86 400 086 0106

USEFUL NIR UV-VIS Troubleshooting Guides & Technical Resources

Part 1- Heptane and Ethyl Acetate

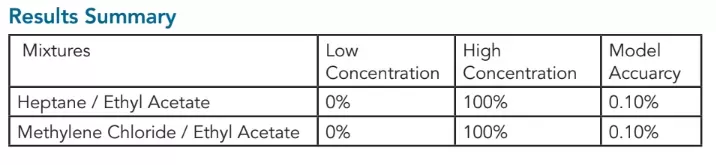

The concentrations of the calibration samples range from 0 – 100% in both Ethyl Acetate and Heptane. The raw spectral data are shown in Figure 1. There are many regions that show changes in the spectral data as a result of the concentration differences. The resulting high correlation coefficients from this spectral data for Heptane and Ethyl Acetate concentrations are a clear indication that the calibration will predict the component concentrations accurately. The resulting calibration model demonstrates a prediction accuracy of +/- 0.10% for both constituents.

Part 2- Methylene Chloride and Ethyl Acetate

The concentrations of the calibration samples range from 0 – 100% in both Ethyl Acetate and Methylene Chloride The raw spectral data is shown in Figure 2. Once again, the spectral data has many regions that show a strong correlation to the component concentrations. Standard calibration modeling techniques produce models with prediction accuracy of approximately +/- 0.10% for both constituents.

Conclusion

We have demonstrated our ability to measure binary solvent mixture concentrations with very good accuracy by NIR spectroscopy. The examples shown here can easily be implemented either as online or laboratory measurements. These measurements can be made with either a full spectrum analyzer such as our GUIDED WAVE™ NIR-O™ or with a smaller photometer unit such as the ClearView® db. The choice between the measurement technologies is dependent on the environment where the measurement is to be made. If strict control and warnings of unusual sample conditions are needed, or if the ability to measure more than 2 physical sample points is required then the full spectrum analyzer is indicated.

For a simple quantitative measurement in a known sample environment, the photometer unit would provide the necessary information. A spectrometer may also be preferred for laboratory measurements where different analytical procedures may be run on a single instrument. In all cases, measurement is facilitated by the remote sample probe and fiber optics. This remote probe capability allows the sample probe to be placed up to one hundred meters away from the analyzer. Robust analyzer hardware eliminates errors related to wavelength instability and drift.

Our comprehensive GUIDED WAVE NIR UV-VIS process and lab analyzer spectrometers offer optically matched components and a meticulously planned calibration approach, ensuring long-term efficiency and cost savings. Our advanced systems are engineered for continuous online operation, delivering real-time data of laboratory-grade quality, even in the harshest processing plant conditions.