Polyurethane Synthesis

Process Analyzer Solution for Polyurethane Synthesis

Polyurethane manufacturing is a high-temperature process conducted under hazardous conditions. A safe and cost-effective method to monitor the polymer synthesis is Near Infrared (NIR) analysis. Using remote insertion probes connected to a NIR analyzer with intrinsically safe fiber optic cables protects the operator from potential safety risks compared to the use of grab samples or sample conditioning systems. Further, our GUIDED WAVE™ SST probes and process shuttle probes were specifically designed to withstand these high temperatures and pressures with low maintenance requirements.

As shown, the process NIR analyzers for polyurethane synthesis offer solutions at multiple monitoring points throughout the industrial monomers and polymerization processes. From water in diisocyanates to end-point reactions, our GUIDED WAVE NIR-O full spectrum analyzer can monitor up to 12 sample locations simultaneously, allowing a single analyzer to do the work of many. Having real-time analyses, without the delay of a grab sample, gives process engineers much greater insight and control over continuous or batch processes and allows for the most efficient and effective processing.

What are Diisocyanates?

Diisocyanates are a family of chemicals used to make a wide range of polyurethane products. The most widely used aromatic diisocyanates are Toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). Less widely used, but still important, are the aliphatic diisocyanates, including hexamethylene diisocyanate (HDI), hydrogenated MDI (H12MDI), and isophorone diisocyanate (IPDI).

- TDI is mainly used to make flexible polyurethane foam that can be found in a wide range of everyday products, including furniture, bedding, carpet underlay, and packaging.

- MDI is used primarily to make rigid polyurethane foams such as insulation boards.

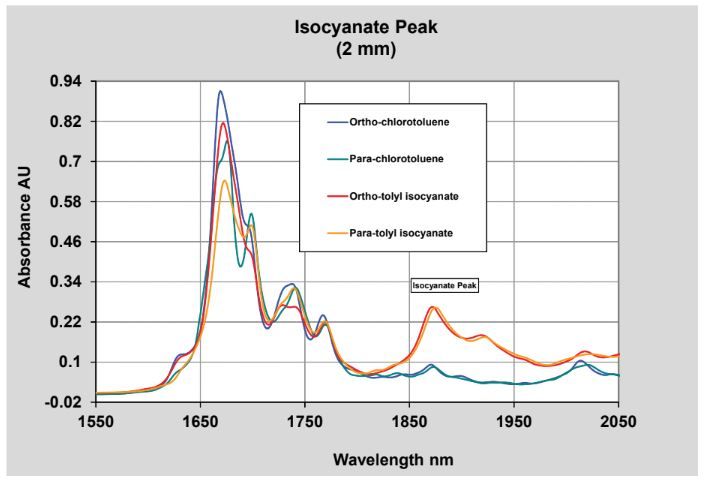

The 1850 nm peak is specific to isocyanate and allows for the reaction to be monitored with a ClearView db Photometer

How Continuous NIR Process Monitoring Improves Yield during Diisocyanate Synthesis

Multiple process points during diisocyanate production can benefit from real-time monitoring with NIR analyzers. For example, the yield of TDI and MDI can be determined. Additionally, the concentration of water which can cause off-spec products to form in the reaction vessel can also be monitored. Once the reaction is complete, the acid number (polyol value) of the prepolymer can be monitored to ensure the product is on-spec.

Improving Operational Safety through Phosgene Leak Detection

Plant safety can be improved by monitoring the purity or concentration of phosgene using our GUIDED WAVE™ High Safety Flow Cell. Built into a Class 300 flange, using welded construction, the GUIDED WAVE High Safety Flow Cell uses double o-ring sealed sapphire windows and a weep or “tattletale” port to self-monitor for O-ring failure. This safety mechanism allows the flow cell to be serviced once the process chemicals are detected in the space between the first and second O-ring seals. Moreover, by installing a High Safety Flow Cell on the input side of the reactor vessel and the recovery line, deviations in the amount of phosgene consumed by the process can be monitored, potentially alerting personnel to a hazardous leak in the facility.

NIR Analyzers can be used for Reaction Endpoint Detection

Determining reaction endpoint in the reactor is critical to achieving desired product properties, such as molecular weight. Knowing exactly when the reaction is complete saves residence time and batch conversion time and lowers the overall manufacturing cost. Having real-time information, without the delay of a grab sample, leads to significant improvements in process control.

How are NIR Analyzers Beneficial to Monoethylene Glycol Synthesis?

Polyurethane synthesis typically starts by combing ethylene oxide and water in a thermal hydration reactor (about 200°C). Near-infrared analyzers can be used to monitor reaction kinetics such as the concentration of excess water as well as the ratio of glycol reaction products. The ethylene oxide to ethylene glycol thermal conversion process typically yields about 90–92% monoethylene glycol (MEG) and 8–10% heavier glycol products, mainly diethylene glycol (DEG) and triethylene glycol (TEG). Near-infrared measurements can be made on the different glycols and also in ethylene carbonate to ethylene glycol reactors.

The resultant water-glycol mixture from the thermal hydration reactor is then fed to multiple evaporators where the excess water is recovered and recycled. Finally, the water-free glycol mixture is separated by vacuum distillation into MEG and the higher glycols. Near-infrared analyzers can be used here to verify yield and other useful parameters.

Determining the Urethane Yield by NIR Analysis

During polyurethane synthesis, isocyanate is reacted with an alcohol to form a urethane. This reaction process creates the carbamate functional group which forms the links in polyurethane. Along with acid number (polyol value), NIR analyzers can be used to monitor the conversion efficiency of isocyanate to urethane.

Monitor Up to 12 Reaction Points with a Single Analyzer

The GUIDED WAVE NIR-O Full Spectrum Analyzer is capable of monitoring up to 12 in situ locations without a stream switching or sample conditioning system. Combining the capabilities of several other analyzers into a single system and running fiber optic cables to each reaction point provides tremendous cost savings.

Interested in Learning More about NIR Analyzer for Polyurethane?

Like many petrochemical reactions, Polyurethane synthesis benefits from continuous monitoring using near-infrared analyzers. Please complete our application questionnaire, so that we can work together to determine how our analyzers can be used to optimize your process and reduce your operating costs.

Our comprehensive GUIDED WAVE NIR UV-VIS process and lab analyzer spectrometers offer optically matched components and a meticulously planned calibration approach, ensuring long-term efficiency and cost savings. Our advanced systems are engineered for continuous online operation, delivering real-time data of laboratory-grade quality, even in the harshest processing plant conditions.