A Single-Supplier Solution For Impurity Monitoring In Fuel-Cell Hydrogen

Global efforts to reduce the impact of harmful emissions on the environment have increasingly focused on lowering carbon emissions. The key to meeting this challenge lies in replacing fossil fuels with alternative, renewable fuel sources, particularly to power vehicles.

Fuel cells offer a uniquely flexible solution in this market and can be used for a wide range of applications, powering systems from laptop computers to utility power stations. The move to a hydrogen economy is widely regarded as the next step in the global transition towards a zero-emission energy sector. A hydrogen fuel cell uses chemical energy to cleanly and efficiently produce electricity; the only byproducts are water and heat. It can also be combined with electric motors to power a zero-emission vehicle.

While most hydrogen (H2) today is still produced from fossil sources, an established H2 infrastructure allows a future seamless transition to renewable and truly carbon-free H2 production. Fuel cells are also far more efficient than conventional combustion engines while offering a similar range (typically, about 500-700 km). H2 can also be refilled quickly at a fueling station, avoiding the delays of charging a battery-electric vehicle.

However, the performance of a fuel cell is dependent on the purity of the hydrogen. There are multiple impurities that can affect the fuel cell, and their presence and concentration levels depend largely upon the method used to generate the H2. For example, most hydrogen is produced through steam methane reforming. This process can generate several contaminants ranging from methane and moisture to carbon monoxide and carbon dioxide (CO2). If H2 is created through electrolysis, splitting water into hydrogen and oxygen, then moisture and oxygen are the most common contaminants. Additionally, many impurities can come from the atmosphere, mostly nitrogen, oxygen, and moisture.

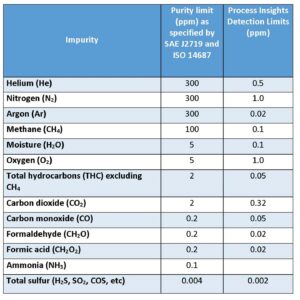

Eliminating impurities from H2 altogether is not practical. Maintaining an efficient fuel cell requires the presence of these contaminants to be limited to specific levels, set by international purity standards such as ISO 14687 or SAE J2719.

It is essential to monitor the wide range of impurities listed in the table above to prevent performance being compromised, or worse, irreparable damage to the fuel cell. In the past, a monitoring solution for H2 purity involved a complex setup using as many as seven different analyzers from multiple providers, with no integration. A typical arrangement requires:

- A gas chromatograph for total sulfur and total halogenates

- Another gas chromatograph for helium, nitrogen & argon, and methane/THC

- An electrochemical analyzer for oxygen

- An FTIR to measure CH2O2, CO and CO2

- Three separate CRDSs, measuring water, ammonia, and CH2O

Process Insights provides a full portfolio of solutions for monitoring hydrogen purity throughout its supply chain, from production, through transport and storage, to fueling. The contaminant detection limits of these instruments are ideally suited to qualify H2 for compliance with global purity standards. The real benefit, however, lies in Process Insights’ total solution. Only three analyzers are required, and these can be fully integrated into one single-provider system.

Our total solution:

- Prismatic 3 multi-species CRDS Analyzer – for CO, CO2, water, and ammonia

- MAX300-LG Mass Spectrometer – for measurements of He, N2, Ar, CH4, O2, CH2O, and CH2O2

- Sulfur & THC Multi-Species GC Analyzer – for total sulfur and total hydrocarbons

The Prismatic 3 multi-species Cavity Ring-Down Spectroscopy (CRDS) analyzer allows simultaneous detection of up to four impurities with wide dynamic ranges, delivering simple, real-time, direct measurements. Highly reliable and with low maintenance requirements, the Prismatic 3 is ideal for remote operations and has a low cost of ownership. Tiger Optics’ analyzers are used to support fuel-cell hydrogen quality control by organizations including the Korean Gas Safety Corporation (KGSC) and California’s Division of Measurement Standards and is approved by ISO.

The MAX300-LG is a compact benchtop mass spectrometer that delivers complete, real-time sample analysis from 100% concentration down to parts-per-billion (ppb) levels. It is supported by our Extrel easy-to-use Questor5 process control software, which is designed for continuous gas monitoring with automated calibrations, analysis sequences, and data outputs.

The combination of Process Insights’ Prismatic 3 analyzer and MAX300-LG mass spectrometer with a Sulfur & THC GC Analyzer to provide the remaining measurements provides a powerful solution for monitoring contaminants in fuel-cell hydrogen. This system dramatically reduces the number of instruments required for measuring hydrogen samples and reduces the cost of manpower and operation through ease of use and low maintenance needs. It also means operators only deal with a single provider, reducing the complexity of ordering, integration, and usage.