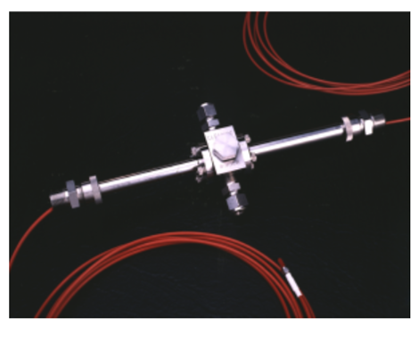

Our Guided Wave Multi-Purpose Flow Cell (MPFC) that is compatible with NIR and UV-VIS Analyzers is available with internal tubing for heating or cooling fluid. While the heat exchanged is not sufficient to impact a rapidly flowing sample, it can be used to maintain the temperature of a preconditioned sample. A version of the MPFC, drilled to accept a heating or cooling fluid, is also available. While the heat exchanged is not sufficient to significantly impact a rapidly flowing sample, it can be used to maintain the temperature of a preconditioned sample.

The MPFC provides exceptional optical performance and is optically matched to all our Guided Wave analyzers Typically, peak transmission exceeds 50%. That means more signal, lower measurement noise translating to lower limits of detection.