PROBE EXTRACTOR MECHANISM

Probe Extractor Mechanism

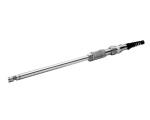

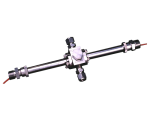

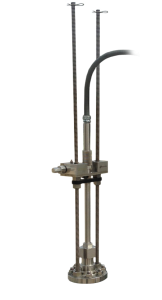

Our GUIDED WAVE™ Probe Extractor Mechanism is used for the controlled extraction/insertion of an in-line probe from pressurized process streams or reactors for servicing. Coupled with a gate or ball valve, these extractors have proven safe and effective in a variety of installations.

DO ALL PROBES REQUIRE SERVICING?

Insertion probes interface the analyzer to the process or sample, and regardless of the manufacturer, all probes used for absorption spectroscopy must be referenced (or zeroed) periodically and the windows occasionally cleaned. Therefore, practical methods for maintenance of the probe or access to the window must be considered when choosing sample interfaces. The Probe Extractor Mechanism makes required maintenance jobs easier, faster and safer.

INSTALLATION EXAMPLES

- Reformer, Gasoline Blending, Blender Feed Streams

- Polyols, Polyesters, Solvent Recovery Applications

HOW DOES THE GEAR-DRIVEN PROBE EXTRACTOR MECHANISM WORK?

The GUIDED WAVE Probe Extractor Mechanism utilizes a pneumatic drill to extract and insert the probe from the assembly via a gear mechanism. It may also be operated by a hand-held crank if drills are not permitted in the areas. When the Probe Extractor Mechanism is purchased with an insertion probe, its conveniently assembled at our factory prior to shipment. This allows installation in the field to be fast and uncomplicated. Shutting down the process just to remove the probe and clean the windows is not possible for most plants. Installing the Probe Extractor Mechanism allows maintenance of the probe while the process is running, providing continuous use of the analyzer to verify process quality.

BENEFITS OF USING THE PROBE EXTRACTOR MECHANISM

- Quick and easy window cleaning without interruption in your process

- Works with insertion probes in service at pressures of up to 700 psi (48 bar)

- Custom extractors with different mounting flanges available

- Custom construction materials available

- Installs easily on a 2-inch Class 300# flange of a gate or ball valve (other options available also)

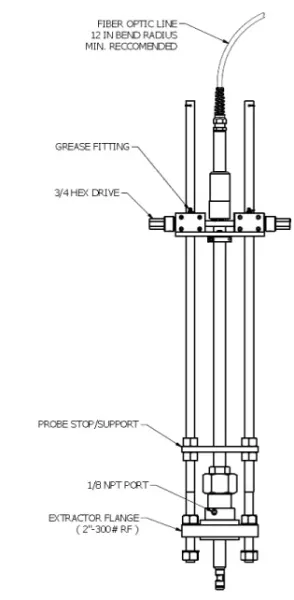

FEATURES OF PROBE EXTRACTOR MECHANISM

- Rapid, safe extraction of in-line probe from pressurized process streams

- 2-inch Class 300 Raised Face Flange

- Teflon “V”-ring packing glands standard

- Dual 3⁄4-inch acme threaded rods for torque free, controlled probe extraction

- Fits both SST and O-SST probes

- Lengths available for 24 inches [61cm] to 36 inch [92cm] probes

- Stainless Steel construction for corrosion free operation (other flange alloys on request)

- Simple 90° speed wrench or pneumatic wrench drive using 3⁄4 inch [19mm] 6-point socket

- Grease fittings to lubricate gears and threaded rods

- Hairpin cotter pins as safety stops for controlled extraction to a safe valve closure location

- 1/8-inch NPT port for installing a pressure gauge and a drain valve to drain dead volume after the process valve is closed

- Speed wrench and socket included

Faster Removal & Servicing of Insertion Probes Without Shutting Down the Process

Faster Removal & Servicing of Insertion Probes Without Shutting Down the Process

USEFUL NIR UV-VIS Troubleshooting Guides & Technical Resources

APPLICATIONS

- Crude Oil Processing

- Water in Solvents

- Polyurethane Synthesis

- Caustic in Water

- Online Monitoring of Saybolt Color with a ClearView db Photometer

- Probes and Flow Cells for Extreme Environments

- Learn how our GUIDED WAVE RUGGED PROBES & FLOW CELLS MEET REFINERY REQUIREMENTS.

- Interested in learning more about our GUDIED WAVE PROBES & FLOW CELL SAFETY STANDARDS?

- Water Analysis in an Alcohol-Brine Solution with a ClearView db Photometer

- Water in Acetic Acid & p-Xylene with a ClearView db Filter Photometer

- Styrene, Acrylonitrile & Methyl-Ethyl-Ketone (Mek) for Online Control on a Styrene Tower

- Ensure Proper Ethylene Glycol Production Yields using NIR Technology

- Improve Yield During Diisocyanate & Urethane Synthesis

- Fast Reliable Measurements of Polyurethanes

- Probes & Flow Cells for Extreme Environments

- Probes and Flow Cells for High Temperature and Hazardous Polymer Measurements

- Inline Transmission Probe For FT-NIR Measurements

- Online Monitoring of APHA Color (ASTM D1209) with a ClearView db Photometer

![NIR UV VIS APPLICATION QUESTIONNAIRE]](/wp-content/themes/yootheme/cache/d4/NIR-UV-VIS-APPLICATION-QUESTIONNAIRE-d40f8301.png)