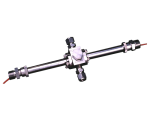

For measuring gases online by spectroscopy, a longer pathlength is usually necessary because of the low density of gaseous streams. A longer cell, while being very effective, is also more difficult to design. For example, transmission probes for gas measurements must be aligned over a greater distance and must permit easy servicing without upsetting the optical focus of the cell. Additionally, many gas streams are considered hazardous making it critical that the sealing mechanism is both reliable and durable. Our GUIDED WAVE™ Gas Process Flow Cell meets or beats most standards for use found in chemical plants, refineries, food, and food supplement processing facilities, semiconductor or electrical component fabrication shops, and pharmaceutical manufacturing plants. Available in a variety of alloys and matched with several elastomeric O-ring types.

Better Optical Efficiency For UV-VIS and NIR Measurements

Descriptively speaking, most true transmission Gas Cells may be viewed in symmetrical halves. Each half comprises both optical and mechanical parts integrally assembled to transmit and receive a focused beam of light that has traversed the sampled stream. The major issues with any kind of transmission flow cell involve establishing and maintaining the optical alignment of the two halves and ensuring that the pathlength is constant and reproducible. When these two issues are resolved well, the result is better optical efficiency. And better optical efficiency leads to significant long-term advantages – more accurate analysis, more robust calibrations, and greatest analyzer uptime.

Features

- Clean out ports at each window.

- Reproducible optical path length permits servicing in the field.

- Rugged design translates to longer service life.

- 25mm diameter optics minimize divergence losses and vignetting.

- High optical throughput for low noise spectroscopy.

Wide Operating Range

Because of its versatility and ruggedness, our GUIDED WAVE Gas Process Flow Cell is the leading option for online spectral analysis in phosgene, HCl, and hydrocarbon gas service. The sturdy design guarantees years of continuous use at high temperatures and pressures. An option to include 6mm thickness windows increases the maximum operating pressure to 1000 psig. While the standard 316L stainless steel material of construction inhibits corrosion due to the elements, a material upgrade to Hastalloy C-276 offers superior resistance to corrosion that can be caused by harsh chemicals.

Sealed Optics for Safety

Perhaps the most crucial aspect of any online probe design is the sealing approach. Since most gas streams will be under pressure and the composition is often hazardous, leaks are most undesirable. Additionally, moisture infiltration from the external environment adversely affects performance too. We implemented a multiple O-ring seal that effectively addresses both issues.

The sample interface is perhaps the most crucial component of any fiber optic-based analyzer system. The GUIDED WAVE Gas Process Flow Cell was designed to minimize the signal loss and level spectral noise due to vibration and stray light making it a smart choice to enhance the overall performance of any analyzer system. For optimal performance, the probe must be “optically matched” with the spectrometer and with the optical fiber that transmits the spectral data. The GUIDED WAVE Gas Process Flow Cell is matched to our analyzers and optical fiber to achieve the highest possible performance.

![NIR UV VIS APPLICATION QUESTIONNAIRE]](/wp-content/themes/yootheme/cache/d4/NIR-UV-VIS-APPLICATION-QUESTIONNAIRE-d40f8301.png)