Rugged, Reliable and Easy Maintenance

Our GUIDED WAVE™ Shuttle Process Probe is a unique and convenient process probe for monitoring liquid samples, in-situ. Rugged, reliable, and easy to use, it is ideal for continuous process monitoring applications where it is difficult and/or costly to shut down the line for probe servicing or where side streams or fast loops are not appropriate. The probe is mounted in a standard size process flange for easy installation. Periodic probe cleaning and referencing can be performed without interrupting the process flow. The Shuttle Process Probe matches perfectly to any of our Guided Wave dual-beam spectrometers and is compatible with many other brands as well.

Unique Operation

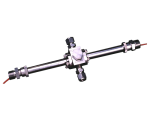

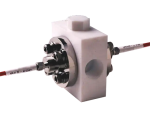

Our GUIDED WAVE Shuttle Process Probe consists of two transmission probes connected by a precision-machined threaded coupler that also functions to accurately set a fixed and reproducible pathlength. After coupling, the two transmission probes become a one-piece sensor that is inserted through the heart of a durable process flange. Carefully engineered gland seals prevent process leakage thus facilitating safe operation. The area where the light interacts with the sample, the sample path, can be easily removed from or “shuttled” out of the process by firm but gentle tugs on either end of the probe. By design the forces are balanced resulting in a negligible ejection force on the probe. Thus, the critical cleaning of the optical windows and subsequent probe referencing are possible without having to interrupt the process.

Process-Resistant Construction

The GUIDED WAVE Shuttle Process Probe is designed to withstand most process conditions. The body of the probe is built from 316L stainless steel or, by special order, other corrosion resistant materials. The probe’s sapphire optical windows are sealed to the probe body using a proprietary gold alloy braze technology. These materials are unaffected by most hydrocarbons and polymers. The threads of the precision coupler that determine the probe’s pathlength and maintain the optical alignment are protected by a double O-ring seal. This prevents process material from entering the threaded area and seizing the coupler in place. The process seals are hydraulic style chevron packing glands, doubled for safety. The fiber connection area is conduit-ready and sealed to prevent moisture infiltration into the back end of the probe.

Wide Operating Range

The GUIDED WAVE Shuttle Process Probe is designed to operate over a range of temperatures and pressures up to the limits imposed by the Class 150 or 300 flange and the gland seal material (typically Teflon). Probe halves are available in four standard lengths: 8”, 12’’, 18’’, and 24” (other lengths are available by special order). The pathlength is determined by the coupler which is available in many standard sizes from 1 to 62 mm. Custom paths are also available upon request.

- Suitable for many processes and measurements

- Allows for in process probe cleaning with no disruption

- Easily change probe pathlengths by changing the coupler

- Install a pair of shuttle probes and a coupler in a shuttle probe flange between 2 flanged sections of pipe

- Compatible with all Guided Wave analyzers

![NIR UV VIS APPLICATION QUESTIONNAIRE]](/wp-content/themes/yootheme/cache/d4/NIR-UV-VIS-APPLICATION-QUESTIONNAIRE-d40f8301.png)