Quantitative Gas Analysis with Quadrupole Mass Spectrometers

News related to Extrel CMS

Written by Terri Melle-Johnson on . Posted in Extrel, Process Insights. No Comments on Quantitative Gas Analysis with Quadrupole Mass Spectrometers

When comparing quadrupole-based gas analyzers for specific applications, consider two main factors: inlet interface suitability and quadrupole mass analyzer performance. Manufacturers often provide inconsistent or incomplete specifications, making it challenging to assess which analyzer is best for reliable and repeatable quantitative gas analysis.

The inlet and interface design ensures the gas analyzer captures, conditions, and transfers the sample without altering it. This ensures accurate measurements across timescales, from milliseconds to hours, through proper upstream transfer elements and downstream pumping components.

Once the inlet and interface are optimized, the quadrupole mass spectrometer becomes the key component, determining the analyzer’s precision, stability, and detection limits. This includes factors like ionization method, transmission characteristics, and electronic performance.

To clarify these differences, we compare two types of quadrupole analyzers: a 6mm rod diameter RGA-type instrument (e.g., MAX300-CAT) and a higher-performance 19mm rod diameter model (e.g., MAX300-LG). By isolating the mass spectrometer’s performance under identical conditions, we highlight practical differences in precision, stability, and detection limits, helping users make informed decisions.

Key Factors to Consider:

The MAX300-CAT, with 6mm quadrupole rods, achieves detection limits of around 5 ppb at slow scan speeds, while the MAX300-LG, using 19mm rods, reaches <1 ppb at slower speeds, with detection limits of <10 ppb at faster scan rates. The MAX300-LG also offers superior precision and stability, making it ideal for demanding applications.

Written by Terri Melle-Johnson on . Posted in Extrel, Process Insights. No Comments on Mass Spec in Semiconductor Fabrication

Ultra-pure gases are crucial for semiconductor fabrication, and continuous monitoring of gas purity ensures maximum production and minimizes costly contamination. Semiconductor manufacturers require real-time verification of process gas purity and detection of trace contamination at low ppt levels.

Our ultra-high purity gas analyzers, such as the Process Insights VeraSpecAPIMS, offer speed, sensitivity, and ease of use to monitor gases like Nitrogen, Argon, Helium, Oxygen, and Hydrogen. The VeraSpecAPIMS uses Atmospheric Pressure Ionization (API) combined with a high-performance mass spectrometer, featuring a 19mm tri-filter quadrupole for optimal performance and reliability.

Benefits of Mass Spec Gas Analyzers:

The VeraSpec APIMS uses corona discharge ionization to ensure exceptional detection limits for trace gases. Combining EI and API ionization techniques, it provides comprehensive analysis of all components in pure gas samples. The Questor5 software enables continuous monitoring with a user-friendly, web-based interface for secure, remote access.

Written by Terri Melle-Johnson on . Posted in Extrel, Process Insights. No Comments on Flare Compliance at Oil Refineries

The EPA Refinery Sector Rule (RSR) update, effective January 30, 2019, requires refineries to monitor flare gas composition more closely. The MAX300-AIR gas analyzer provides rapid, detailed analysis of vent gases to help refineries meet these new compliance standards. Flares used for Air Pollution Control Devices (APCD) must achieve 98% Hazardous Air Pollutant (HAP) destruction efficiency. The updated rule also includes monitoring of parameters like pilot flame, visible emissions, and net heating values (NHV).

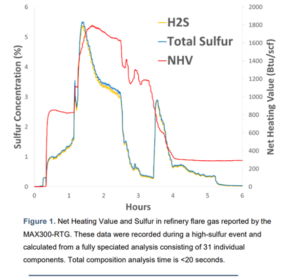

The Net Heating Value of the gas in the Combustion Zone (NHVCZ) directly affects combustion efficiency, with a required NHVCZ ≥ 270 Btu/scf for at least 15 minutes. For flares with assist air, NHVdil must meet a specific threshold. Continuous, direct measurements are needed to meet these requirements. The MAX300-RTG 2.0 real-time gas analyzer, used in many US refineries, provides continuous updates of NHV, H2S, and Total Sulfur, helping refineries stay compliant and improve operational control.

The regulation offers multiple ways to calculate the Net Heating Value of the gas in the Combustion Zone (NHVCZ) for RSR reporting, but all methods rely on the Net Heating Value of the Vent Gas (NHVVG) as a key input. Parameters such as NHVCZ, NHVdil, and maximum flare tip velocity (Vmax) depend on NHVVG, making it crucial for both compliance and effective flare control. Direct measurements of vent gas composition allow accurate calculation of NHVVG, and precise gas analysis ensures reliable data. When regulated material is sent to the flare, NHVVG fluctuates as hydrogen and hydrocarbon concentrations rise and fall. The MAX300-RTG analyzer provides consistent, high-precision NHV measurements, ensuring reliable data despite variations in the gas composition.

Written by Terri Melle-Johnson on . Posted in Extrel, Process Insights. No Comments on Fenceline Air and Flare Gas Monitoring

Environmental Applications for Real-Time Mass Spectrometer Gas Analyzers

Recent updates to 40 CFR 60 and 63 have increased EPA regulations on flare gas and fenceline monitoring. This has led to a need for real-time gas analysis solutions at oil refineries and hydrocarbon manufacturing plants.

Industrial mass spectrometers provide fast, continuous updates on compliance parameters. They also offer critical insights for process safety and control. This presentation covers real-world applications, such as fenceline, flare gas, fuel gas, and air monitoring, using real-time mass spectrometer gas analyzers.

Mass spectrometry identifies and quantifies substances based on molecular mass. Gases and vapors are ionized in a vacuum chamber. Electric fields filter the ions. Selected ions reach the detector, and gas composition is calculated and reported in real-time.

Mass spectrometers are versatile and fast. They can analyze any class of molecules. With one analyzer, you can monitor multiple sample points, saving on hardware and maintenance costs.

Written by Terri Melle-Johnson on . Posted in Extrel, Process Insights. No Comments on Monitoring Gasification with a Mass Spec Gas Analyzer

Research in the field of biomass gasification is increasingly important as industry continues to find new uses for syngas. At the Energy & Environmental Research Center (EERC) an Extrel MAX300-RTG process mass spectrometer was used to monitor the exit stream of a Fluid Bed Gasifier. The quadrupole mass spectrometer provided fast, quantitative analysis of the syngas composition.

Over the last several years, concern about the economic and environmental impact of traditional fossil fuel combustion and petrochemicals has led to a search for viable alternatives with gasification emerging as a powerful technique for generating fuel and hydrocarbons. The gasification process makes use of materials such as coal, biomass, and waste to produce synthesis gas, or syngas. Syngas is a combustible mixture of hydrogen, carbon monoxide and carbon dioxide that generally contains a small amount of methane and some trace contaminants. Syngas is used as a fuel source to generate power and heat, or converted into products like hydrogen, for use in fuel cells or fertilizer generation, or liquid fuels via a Fischer-Tropsch reaction.

Gasification and chemical processes utilizing syngas rely upon the ability to obtain information about the composition of the gas stream exiting the reactor. The MAX300-RTG is a 7th generation process mass spectrometer capable of performing quantitative analysis on a wide variety of compounds at concentrations ranging from 100% down to 10 ppb. The 19 mm quadrupole mass filter used by the system allows for high analytical repeatability and long-term stability.

The MAX300-RTG demonstrated that it has the flexibility to quickly characterize and quantify syngas mixtures. It has the sensitivity to detect trace components at ppm levels and below, and the speed to perform each measurement in under 0.4 seconds. The ability to analyze the complete array of syngas components exiting the gasifier, from 100% down to ppm levels, makes the MAX300-RTG an instrument capable of replacing complicated analysis systems involving multiple devices and technologies. The speed of the mass spectrometer means that the MAX300-RTG can be automated to monitor gas composition at several sample points, delivering a complete set of concentrations at 20 seconds per point.

At the EERC, additional sampling at the ports downstream of the reactor could yield important insight into the operation and efficiency of the fixed beds, or be used to analyze hydrogen membrane separation, or a Fischer-Tropsch product. The speed and flexibility of the MAX300-IG, combined with the capability to run 24/7 in rugged and hazardous industrial environments, make it ideal for monitoring production scale gasification and any associated chemical processes downstream. At large facilities that utilize syngas, like ammonia plants, the MAX300-RTG and its predecessors have set the standard for analyzer automation and process control over the last several decades.

Written by Terri Melle-Johnson on . Posted in Extrel, Process Insights. No Comments on Thermogravimetric Analysis/Mass Spectrometry (TGA-MS)

The heated transfer line of the MAX300-EGA™, a quadrupole mass spectrometer designed for evolved gas analysis, was connected to the off-gas port of a NETZSCH® TG 209 F1 Libra® thermobalance. A variety of samples were analyzed and the combination of the two technologies allowed for simultaneous thermal characterization and quantitative analysis of the compounds in the furnace exhaust.

Thermogravimetric analysis (TGA) is a powerful technique that has been used for many years to characterize solid and liquid samples. The mass of the sample material is monitored while it is heated. By using a high precision balance and carefully controlling the heating process, researchers are able to plot mass loss as a function of temperature. TGA is widely used in the study of polymers, pharmaceuticals and petrochemicals to determine degradation temperatures, characterize thermal decomposition, and monitor solvent and moisture content.

Additional information about sample composition and thermal behavior can be obtained by analyzing the gases that leave the material as it is heated. This allows the researcher to determine not only the temperature at which a mass loss occurs, but also the molecular structures involved. Evolved Gas Analysis (EGA) is commonly carried out via a variety of analytical techniques, but in all cases the integrity of the gas stream must be protected. It must be kept hot and moved quickly to the gas analyzer to prevent condensation and chemical interactions.

The NETZSCH TG 209 F1 Libra is a vacuum tight TGA, making it ideal for connecting to a mass spectrometer. The Libra is equipped with an automatic sample changer and can reach temperatures up to 1100°C. It measures sample mass to a resolution of 0.1 μg. The Libra’s heated adapter was connected to the transfer line of the Extrel MAX300-EGA. The interface is differentially pumped for rapid clearing and heated to 200°C to prevent condensation; it provides a low volume, chemically inert sample path from the TGA all the way into the mass spectrometer’s ionizer.

The MAX300-EGA is a quadrupole mass spectrometer optimized for evolved gas analysis in a laboratory setting. It is capable of scanning from 1-500 amu and features the Extrel 19 mm mass filter for high analytical repeatability and long-term stability. The Questor5 software allows the system to perform qualitative analysis for sample characterization, or quantitative analysis, measuring concentrations from 100% down to 10 ppb. In addition to the transfer line, a MAX300-EGA is equipped to import a start-of-heating signal from the TGA and can be configured to perform calculations and trend data or output the data for viewing and manipulation on a different platform.

The furnace of the Libra was loaded with 0.94 mg of polystyrene and heated to over 600°C. The breakdown of the sample was monitored to determine the MAX300’s sensitivity to the small signals generated by high-mass hydrocarbons in the off-gas. Although the TGA records the decomposition of the polystyrene as a single weight loss beginning at 290°C, the MAX300 is able to show that the evolution of several compounds has occurred.

It is generally difficult to keep larger molecules from dropping out of an evolved sample once it has left the furnace, but the mass spectrum at 39.75 minutes clearly shows the presence of styrene in the off gas (Fig. 3. B), as well as the much smaller signal generated by methyl styrene.

The mass of each component in the gas was calculated for comparison to data from the TGA’s balance. Even the relatively small, 60 μg, loss that occurred as moisture left the sample was easily measured and quantified by the mass spectrometer. The MAX300 was also able to individually determine the amount of carbon monoxide and carbon dioxide that, combined, resulted in the second mass loss. While the thermal breakdown of calcium oxalate is well documented, the ability of the MAX300 to perform similar quantitative separations can be used to better understand a complex decomposition featuring the simultaneous evolution of multiple unknown compounds.

The data gathered from the effluent of the TGA 209 F1 Libra indicates that the MAX300-EGA is a powerful tool for evolved gas analysis. The sensitivity, resolution and quantitation demonstrated during the tests indicate the instrument’s potential for other evolved gas applications. In its standard configuration or equipped with the 300 or 400°C transfer line upgrades, the MAX300-EGA could be used to quantify solvent loss in a pharmaceutical sample, detect trace VOCs, or monitor the gas exiting a microreactor.