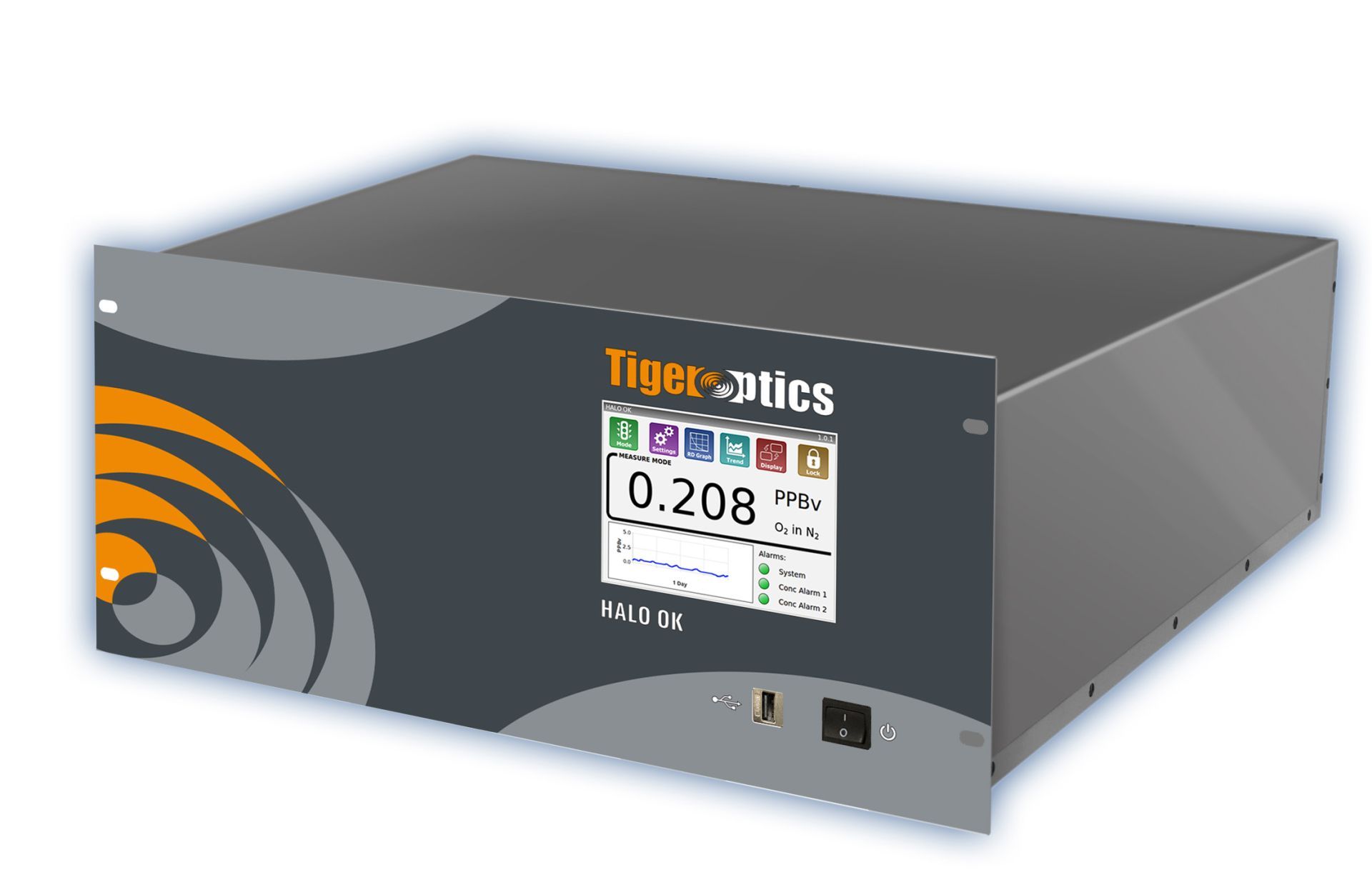

HALO OK

Trace-Level Oxygen CRDS Analyzer

CRDS Laser-Based Analyzer

LEADING CHOICE FOR ULTRA-HIGH PURITY GAS USERS FOR TRACE OXYGEN DETECTION

Detect gas quality upsets before they damage your process. Using our TIGER OPTICS™ HALO™ OK trace-level oxygen analyzer, you can verify oxygen impurity levels with part-per-trillion accuracy, drift-free stability and instantaneous response. You’ll find our system exceptionally easy and fast to install, and effortless to maintain, with built-in zero verification. Its robust design—free of moving parts—results in an analyzer that has a high Mean Time Between Failure (MTBF) rate and a very low Cost of Ownership (CoO).

With its patented catalytic conversion technique, utilizing a minute amount of hydrogen to cleanly and safely convert oxygen to moisture, the HALO OK offers a fully laser-based solution for Continuous Quality Control of your process. Based on powerful Cavity Ring-Down Spectroscopy, the HALO OK aligns with the SEMI F-112 standard for moisture dry-down characterization of gas systems. Pair the new Halo OK with our Halo KA for ppt-level moisture measurement to enjoy the many advantages of profit-boosting CRDS technology for both critical contaminants.

DESIGNED FOR TRACE-LEVEL OXYGEN ANALYSIS, THE HALO OK OFFERS:

- Industry-leading parts-per-trillion detection capability

- Unprecedented speed of response

- Wide dynamic range

- Absolute measurement (freedom from need for calibration gases)

- Low maintenance and cost of ownership

- Compact, portable package, ideal for both fixed and mobile cart installation

- Direct measurement in many matrices

APPLICATIONS

- Gas Quality Control

- Gaseous CRMs & Calibration Gas Mixtures

- High-Purity Gases & Systems

- Hydrogen Fuel Cells

- Research & Development

DETECTION CAPABILITY

| Detection and Matrix | Range | LDL (3σ)† | Precision (1σ) @ zero | |||

|---|---|---|---|---|---|---|

| Standard Model (using pure H2 utility gas) | ||||||

| O2 in He | 0 – 0.5 ppm | 50 ppt | 17 ppt | |||

| O2 in Ar | 0 – 1 ppm | 90 ppt | 30 ppt | |||

| O2 in H2 | 0 – 2 ppm | 150 ppt | 50 ppt | |||

| O2 in N2 | 0 – 2.5 ppm | 200 ppt | 70 ppt | |||

| CO2 Model (using pure H2 utility gas) | ||||||

| O2 in He | 0 – 0.5 ppm | 50 ppt | 17 ppt | |||

| O2 in Ar | 0 – 1 ppm | 90 ppt | 30 ppt | |||

| O2 in H2 | 0 – 2 ppm | 150 ppt | 50 ppt | |||

| O2 in N2 | 0 – 2.5 ppm | 200 ppt | 70 ppt | |||

| O2 in CO2 | 0 – 5 ppm | 5000 ppt‡/1000 ppt§ | 300 ppt | |||

| Enhanced Safety Model (using 3% H2/97% N2 mixture utility gas) | ||||||

| O2 in He | 0 – 0.5 ppm | 400 ppt‡ | 17 ppt | |||

| O2 in Ar | 0 – 1 ppm | 400 ppt‡ | 30 ppt | |||

| O2 in H2 | 0 – 2 ppm | 400 ppt‡ | 50 ppt | |||

| O2 in N2 | 0 – 2.5 ppm | 400 ppt‡ | 70 ppt | |||

†LDL is dependent upon the quality of the sample gas and the integrity of the sampling system.

‡LDL is limited by minimum achievable O2 concentration, not by 3σ baseline noise.

§LDL of 1000 ppt requires addition of Tiger Optics’ Zero Gas Panel and Linear Fit Mode. Please contact us for more information.

We also offer a new CRDS analyzer performance upgrade. Implementing our new intelligent dynamic data processing, the Speed+™ Analyzer Performance Upgrade Software adjusts your analyzer’s response automatically and in real-time to deliver the best performance. Benefits of Speed+ for your operations include real-time process control to ensure quality, as well as faster throughput and increased capacity to improve efficiency and profitability.

ANALYZE WITH EASE™

TRACE OXYGEN DETECTION FOR UHP GASES

ANALYZE WITH EASE™

TRACE OXYGEN DETECTION FOR UHP GASES

Learn about our service, technical support, spares, and our CRDS Analyzer | Performance Verification Program

Analyzer in service? Need a rental CRDS analyzer? Ask us how we can help.

SOLUTIONS FLYERS

-

AGRICULTURE

-

CHEMICAL

-

ENERGY

-

FOOD & BEVERAGE

-

FLARE GAS

-

INDUSTRIAL GAS

-

LAB & RESEARCH

-

PHARMACEUTICALS & LIFE SCIENCE

-

REFINERY

-

SEMICONDUCTOR

-

SPECIALTY GAS