Crude oil naturally contains benzene, which serves as a valuable chemical solvent and feedstock. However, due to its significant health risks, regulations restrict its presence in many common products, especially gasoline. Authorities enforce strict concentration limits and require accurate measurements.

Gas chromatography (GC) is the traditional method for measuring benzene, but it demands significant time and labor. This note explores how our hardware and software tools measure % Benzene in fuel products using fiber-optic-based Near-Infrared (NIR) spectroscopy. NIR enables real-time process monitoring or laboratory analysis, offering a faster and more cost-effective alternative to traditional methods.

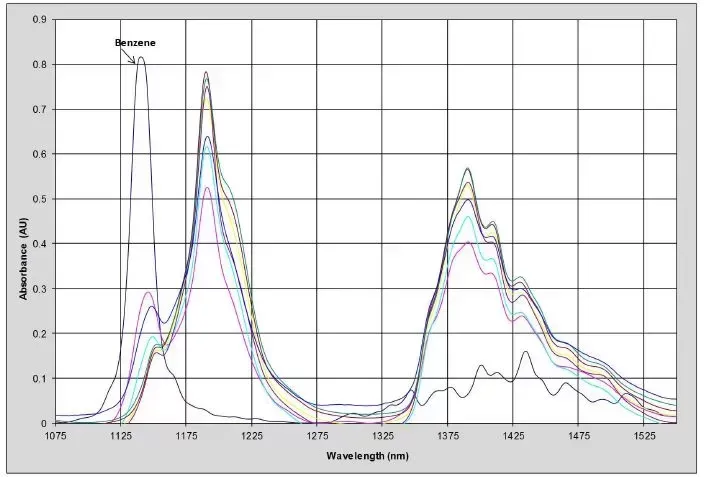

The team submitted the spectra and concentration data to third-party software and developed a calibration model using PLS regression methodology. For more on PLS and other multivariate calibration techniques, see Martens and Naes¹ and ASTM E16552.

The model predicted benzene concentrations using an in-situ probe placed in a process stream for real-time measurement. Figure 2 presents the results as a scatter plot, while Figure 3 shows them as a trend plot. The model achieved a prediction RMSEP (root mean square error of prediction) of 0.30% benzene, aligning well with the accuracy of the standard laboratory method.

The measurement of benzene in gasoline using NIR spectroscopy is both fast and reliable utilizing the our hardware and software tools as described here. This method minimizes the need for laboratory sample collection. Results are available in real-time (seconds) for multiple parameters in complex streams. For more detailed information regarding system specifications please contact a Process Insights sales or technical specialist.

References

AMERICAS: info.americas@process-insights.com

EMEAI (includes India): info.emeai@process-insights.com

APAC: info.apac@process-insights.com

CHINA: info.cn@process-insights.com