How to select an analyzer

How to Select an Analyzer

Helping You Select the Right NIR, UV-VIS OR FT-NIR Analyzer for your Application

Selecting a light, or spectroscopy, based in-line process analyzer can be an intimidating task. We suggest you start by asking:

- What is the difference between a photometer and a spectrometer?

- What wavelengths do I need to monitor for my application?

- Do I need to buy a UV-VIS, NIR, or FT-NIR analyzer?

To aid you in the decision-making process, we developed a simple three-step process to answer these questions. Once these questions are answered, you can confidently move on to comparing technologies.

Step 1 – What is being measured?

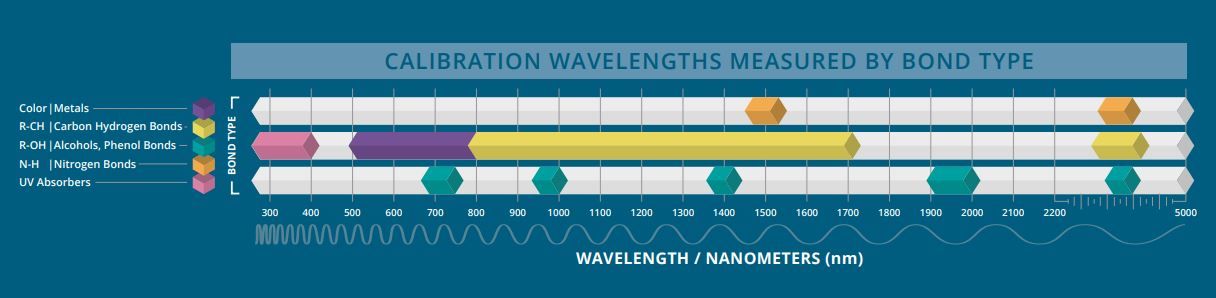

The first step in selecting the proper analyzer for an application is achieved by identifying what properties and chemical species of the process you want to monitor. Use the image below to locate as many wavelengths as possible that match the chemical structures of interest.

- PURPLE = Color and Metal Complex

- YELLOW = Organic carbon-hydrogen bonds

- BLUE = Water, Alcohol, and Phenol bonds

- ORANGE = Nitrogen Bonds

- PINK = UV absorbers such as Chlorine

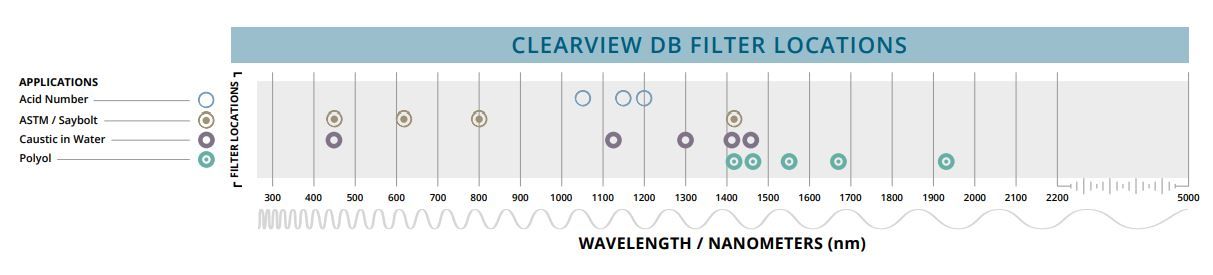

The discrete wavelengths for four common ClearView db applications:

- WHITE: Acid Number

- GRAY: ASTM or Saybolt Color

- BLUE: Polyol

- PURPLE: Caustics in water

Clearview DB Measurement Application Solutions

Photometers:

- Such as the ClearView db use a fixed number of solid-state optical filters to monitor up to 6 discrete wavelengths.

- Provide a cost-saving option for less complex processes.

508plus Measurement/ Application Solutions

- Monitoring Triazines and their Precursors

- Trace Copper Contamination

NIR-O Measurement/ Application Solutions

- Plastics End-Point Monitoring

- Solvent Composition

- Acrolein Process (water in reaction)

- Refinery Physical properties (RON/MON and Fuel Identification)

Step 2A – Identify the Corresponding Analyzer

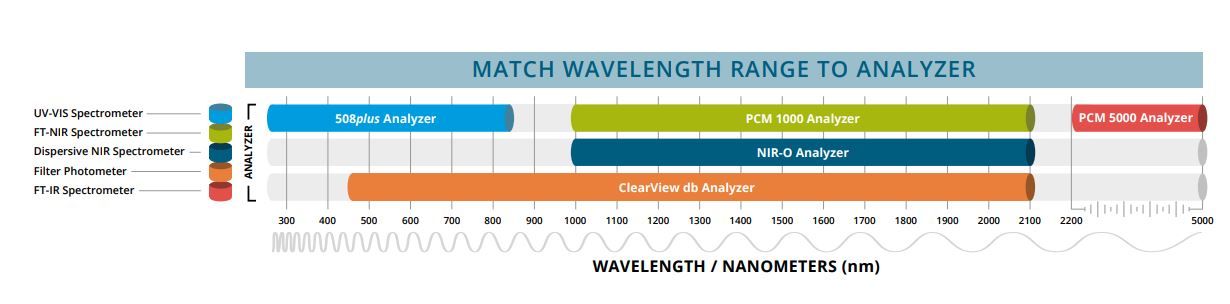

Now that the wavelengths of interest have been identified, simply match those wavelengths to an analyzer that can measure them. The image above indicates the wavelength range covered by the UV-VIS 508plus Spectrometer, the NIR-O Full Spectrum Near-Infrared Analyzer, PCM1000, PCM 5000 and the Dual Beam Clearview Photometer. If less than 6 wavelengths were identified, then a ClearView db can possibly provide a cost-saving solution for real-time monitoring of process conditions.

Step 2B – Quick View and Comparison Selection Guide:

Still unsure which analyzer is best or your application?

Now you can compare some high-level specifications such as the number of simultaneous sample points, wavelength range, technology type, the number of traits or answer the analyzer can monitor at each sample location.

| ANALYZER PURPOSE OR APPLICATION | 508plus | CLEARVIEW® DB | NIR-O | PCM 1000 | PCM 5000 |

|---|---|---|---|---|---|

| Wavelength Range required for measurements | UV-VIS 200-850-nm | VIS - NIR 450-2150 nm | NIR 1000-2100 nm | FT-NIR 12000 -1200 CM-1 (1000-2100 NM) | MIR 7000-450 CM-1 (> 2100 NM) |

| Fourier Transform Spectrometer | X | X | |||

| Diode Array - Spectrometer | X | ||||

| Full Spectrum - DG-NIR Spectrometer | X | ||||

| Dedicated Spectrum - Filter Photometer | X | ||||

| Complex Samples with Variable Chemistries | X | X | X | X | |

| Complex Samples with Many Measurements | X | X | X | X | |

| Simple Well-Characterized Process | X | ||||

| Number of Measurements (answers / results) | 16 per Channel | 6 | 8 | >8 | >8 |

| Maximum Number of Sample Points (locations) | 4 | 2 | 12 | 8 | 27 |

Step 3 – Contact Us

The Final Step

- Complete the Application Questionnaire to provide us with the information we need to design a complete process monitoring solution.

- Or, fill out the Contact Us Form.

We’re here to help and answer your questions.